ASTM F468 Bolts are commercial-grade wrought non-ferrous fasteners manufactured as per ASTM F468 and ASME SF468 standards. These fasteners include hex bolts, cap screws, studs, and anchor bolts, produced from corrosion-resistant alloys with controlled chemical composition.

ASTM F468 fasteners are widely used for general engineering and industrial applications where strength, corrosion resistance, and dimensional accuracy are required. Each ASTM F468 Bolt complies with strict mechanical and chemical requirements defined by the specification.

ASTM F468 UNS N06625 & Non-Ferrous Bolts Supplier and Exporter in India

ASTM F468 Bolts are manufactured by cold forming, hot forging or precision machining depending on size and the grade of material. They are generally tested on tensile strength, yield strength, hardness, and elongation, and they should all perform consistently.

Nickel alloys, stainless steel, copper alloys and Monel are non-ferrous materials that are of good corrosion resistance and durability qualities. ASTM F468 Flange Bolts and Anchor Bolts are lightweight and flexible and therefore suitable in situations where a reduction in weight is very important.

Jade Alloys is a reputed supplier of ASTM F468 Bolts and ASME SF468 Bolts in India in a variety of sizes, materials, and finishes. We provide standard and custom ASTM F468 fasteners with full traceability and test certificates and international export packaging.

Looking to buy Bolts?

Check Stainless Steel Bolts, Alloy Steel Bolts & Carbon Steel Bolts Price List in India

Nuts Weight Chart

Quick Section Links

- ASTM F468 Bolts Types

- ASME SF468 Bolts Specifications

- ASTM F468 Bolts Material

- ASME SF468 Bolts Size Chart

- ASTM F468 Hex Bolt Dimensions

- ASTM F468 Heavy Hex Bolt Dimension

- ASME SF468 Bolts Chemical Composition

- ASTM F468 Bolts Mechanical Properties

- ASME SF468 Material Applications

- ASTM F468 Bolts Price In India

ASTM F468 Bolts Types

ASME F468 UNS C46200 Hex Bolt

F468 UNS N05500 Anchor Bolt

ASTM F468 N10276 Stud Bolt

F468 Inconel 625 Screw

ASTM F468 Monel 400 Hex Head Bolt

ASTM F468 UNS N06625 Studs

F468 N05500 Washers

ASTM F468M Nuts

ASME F468 C46200 Threaded Rod

ASME SF468 Bolts Specifications

| Standards | Designation |

|---|---|

| ASTM | F468 |

| Thread Requirements | ASME B1.1, UNC & UNF, Class 2A (Fastenal will inspect and accept parts with a 1A no-go gauge) |

| Manufacturing Process | Wire Drawing, Cold Heading, Insert tapping, Heat Treatment, Surface Plating, Inspection, Packing |

| Coatings | Black Oxide, Cadmium, Galvanized, Teflon, Xylan, Zinc, Others Upon Request |

| Head | Hex, Square, Round, Hex flange, Flat, T-head & Triangular etc |

| Neck type | Hex, Square, Triangular, Oval & Knurled etc |

| Dimensions | ASME B18.2.1, B18.3 |

| Certification | Dual Certified As per ASTM & ASME Codes |

ASTM F468 Bolts Material

| Material | Grades |

|---|---|

| Stainless Steel | AISI 302, 304 / 304L, 316 / 316L, 317 / 317L, 310, 321, 347, 410, 420, 904L |

| Duplex & Super Duplex Steel | ASTM / ASME A815 – UNS S31803, S31550, S31254, S32205, S32750, S32760 |

| Carbon Steel | ASTM A307 |

| Alloy Steel | ASTM / ASME A193 / A194 – B6, B7, B7M, B16, 2, 2H, 2HM, Grade 6 |

| Nickel Alloys | ASTM / ASME SB 160, 164, 166, 425, 446, 472, 574 UNS N04400 (Monel 400), N06600 (Inconel 600), N06601 (Inconel 601), N08825 (Inconel 825), N02200 / N02201 (Nickel 200 / 201), N10276 (Hastelloy C276), N06625 (Inconel 625), N08020 (Alloy 20) |

ASME SF468 Bolts Size Chart

| Metric | Closest Inch |

|---|---|

| M1.4-0.3 | 0-80 (Larger) |

| M2-0.4 | 1-64 (Smaller) |

| M2.5-0.45 | 3-56 (Larger) |

| M3-0.5 | 4-48 (Smaller) |

| M3.5-0.6 | 6-40 (Same) |

| M4-0.7 | 8-36 (Larger) |

| M5-0.8 | 10-32 (Smaller) |

| M6-1.0 | 1/4-28 (Larger) |

| M7-1.0 | 1/4-28 (Smaller) |

| M8-1.25 | 5/16-18 (Smaller) |

| M10-1.5 | 3/8-16 (Smaller) |

| M12-1.75 | 1/2-13 (Larger) |

| M14-2.0 | 9/16-12 (Larger) |

| M16-2.0 | 5/8-11 (Smaller) |

| M18-2.5 | 3/4-10 (Larger) |

| M20-2.5 | 3/4-10 (Smaller) |

| M22-2.5 | 7/8-9 (Larger) |

| M24-3.0 | 1-8 (Larger) |

| M30-3.5 | 1 1/8-7 (Smaller) |

| M36-4.0 | 1 3/8-6 (Smaller) |

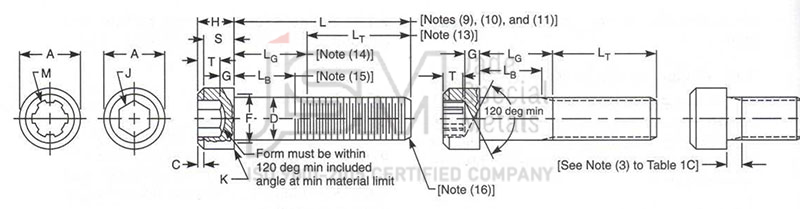

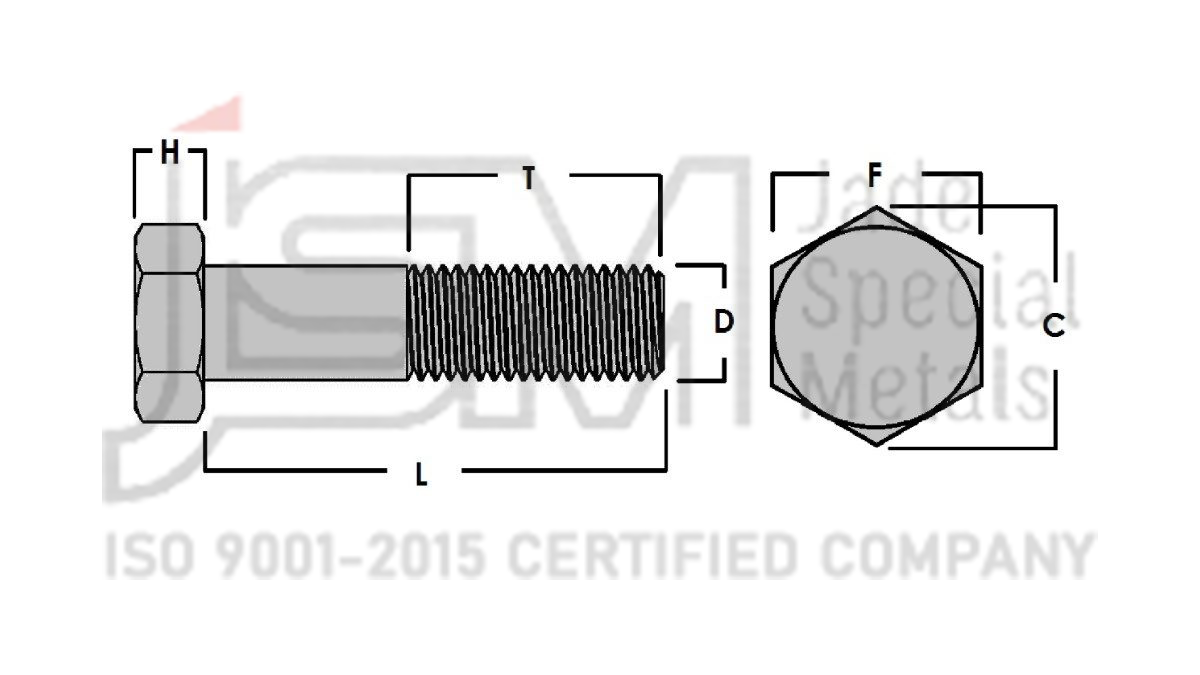

ASTM F468 Hex Bolt Dimensions

| NOMINAL SIZE (D) | BODY DIAMETER | HEAD THICKNEASTM F468 | ACROASTM F468 THE FLATS | ACROASTM F468 CORNERS | ||||

|---|---|---|---|---|---|---|---|---|

| D (MAX) | D (MIN) | H (MAX) | H (MIN) | F (MAX) | F (MIN) | C (MAX) | C (MIN) | |

| m10 | 10.00 | 9.78 | 6.63 | 6.17 | 17.00 | 15.73 | 18.48 | 17.77 |

| m12 | 12.00 | 11.73 | 7.76 | 4.24 | 19.00 | 17.73 | 20.78 | 20.03 |

| m14 | 14.00 | 13.73 | 9.09 | 8.51 | 22.00 | 20.67 | 24.25 | 23.35 |

| m16 | 16.00 | 15.73 | 10.32 | 9.68 | 24.00 | 23.67 | 27.71 | 26.75 |

| m20 | 20.00 | 19.67 | 12.88 | 12.12 | 30.00 | 29.16 | 34.64 | 32.95 |

| m24 | 24.00 | 23.67 | 15.44 | 14.56 | 36.00 | 35.00 | 41.57 | 39.55 |

| m30 | 30.00 | 29.67 | 19.48 | 17.92 | 46.00 | 45.00 | 53.12 | 50.85 |

| m36 | 36.00 | 35.61 | 23.38 | 21.63 | 55.00 | 53.80 | 63.51 | 60.79 |

| m42 | 42.00 | 41.38 | 26.97 | 25.03 | 65.00 | 62.90 | 75.06 | 71.71 |

| m48 | 48.00 | 47.38 | 31.07 | 28.93 | 75.00 | 72.60 | 86.60 | 82.76 |

| m56 | 56.00 | 55.26 | 36.2 | 33.80 | 85.00 | 82.20 | 98.15 | 93.71 |

| m64 | 64.00 | 63.26 | 41.32 | 38.68 | 95.00 | 91.80 | 109.70 | 104.65 |

| m72 | 72.00 | 71.26 | 46.45 | 43.55 | 105.00 | 101.40 | 121.24 | 115.60 |

| m80 | 80.00 | 79.26 | 51.58 | 48.42 | 115.00 | 111.00 | 132.72 | 126.54 |

| m90 | 90.00 | 89.13 | 57.74 | 54.26 | 130.00 | 125.50 | 150.11 | 143.07 |

| m100 | 90.00 | 99.13 | 63.9 | 60.10 | 145.00 | 140.00 | 167.43 | 159.60 |

ASTM F468 Heavy Hex Bolt Dimension

| Diameter (D) | Body Diameter (D) | Across the Flats (F) | Across the Corners © | Head Height (H) | Thread Lengths (T) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| MAX | MIN | MAX | MIN | MAX | MIN | MAX | MIN | <6” | >6” | |

| 1/2 | 0.515 | 0.482 | 0.875 | 0.85 | 1.01 | 0.969 | 0.364 | 0.302 | 1.25 | 1.5 |

| 5/8 | 0.642 | 0.605 | 1.062 | 1.031 | 1.227 | 1.175 | 0.444 | 0.378 | 1.5 | 1.75 |

| 3/4 | 0.768 | 0.729 | 1.25 | 1.212 | 1.443 | 1.383 | 0.524 | 0.455 | 1.75 | 2 |

| 7/8 | 0.895 | 0.852 | 1.438 | 1.394 | 1.66 | 1.589 | 0.604 | 0.531 | 2 | 2.25 |

| 1 | 1.022 | 0.976 | 1.625 | 1.575 | 1.876 | 1.796 | 0.7 | 0.591 | 2.25 | 2.5 |

| 1 1/8 | 1.149 | 1.098 | 1.812 | 1.756 | 2.093 | 2.002 | 0.78 | 0.658 | 2.5 | 2.75 |

| 1 1/4 | 1.277 | 1.223 | 2 | 1.938 | 2.309 | 2.209 | 0.876 | 0.749 | 2.75 | 3 |

| 1 3/8 | 1.404 | 1.345 | 2.188 | 2.119 | 2.526 | 2.416 | 0.94 | 0.81 | 3 | 3.25 |

| 1 1/2 | 1.531 | 1.47 | 2.375 | 2.3 | 2.742 | 2.622 | 1.036 | 0.902 | 3.25 | 3.5 |

| 1 3/4 | 1.785 | 1.716 | 2.75 | 2.662 | 3.175 | 3.035 | 1.196 | 1.054 | 3.75 | 4 |

| 2 | 2.039 | 1.964 | 3.125 | 3.025 | 3.608 | 3.449 | 1.388 | 1.175 | 4.25 | 4.5 |

| 2 1/4 | 2.305 | 2.214 | 3.5 | 3.388 | 4.041 | 3.862 | 1.548 | 1.327 | 4.75 | 5 |

| 2 1/2 | 2.559 | 2.461 | 3.875 | 3.75 | 4.474 | 4.275 | 1.708 | 1.479 | 5.25 | 5.5 |

| 2 3/4 | 2.827 | 2.711 | 4.25 | 4.112 | 4.907 | 4.688 | 1.869 | 1.632 | 5.75 | 6 |

| 3 | 3.081 | 2.961 | 4.625 | 4.475 | 5.34 | 5.102 | 2.06 | 1.815 | 6.25 | 6.5 |

ASME SF468 Bolts Chemical Composition

Copper and Copper Base Alloys

| Composition, % Copper and Copper Base Alloys | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| UNS Designation | Alloy | General Name | Aluminum | Copper, min | Iron, max | Manganese, max | Nickel, max | Phosphorus | Silicon | Zinc, maxA | Lead, max | Tin | Arsenic, max |

| C11000 | 110 | ETP Copper | — | 99.9 | — | — | — | — | — | — | — | — | — |

| C26000 | 260 | Brass | — | 68.5 – 71.5 | 0.05 | — | — | — | — | balance | 0.07 | — | — |

| C27000 | 270 | Brass | — | 63.0 – 68.5 | 0.07 | — | — | — | — | balance | 0.10 | — | — |

| C46200 | 462 | Naval Brass | — | 62.0 – 65.0 | 0.10 | — | — | — | — | balance | 0.20 | 0.50 – 1.00 | — |

| C46400 | 464 | Naval Brass | — | 59.0 – 62.0 | 0.10 | — | — | — | — | balance | 0.20 | 0.50 – 1.00 | — |

| C51000 | 510 | Phosphor Bronze | — | balanceA | 0.10 | — | — | 0.03 – 0.35 | — | 0.30 | 0.05 | 4.20 – 5.80 | — |

| C61300 | 613 | Aluminum Bronze | 6.0 – 7.5 | B | 2.0 – 3.0 | 0.10 | 0.15C | 0.015 | 0.10 | 0.05 | 0.01 | 0.20 – 0.50 | — |

| C61400 | 614 | Aluminum Bronze | 6.0 – 8.0 | 88.0D | 1.5 – 3.5 | 1.00 | — | — | — | — | — | — | — |

| C63000 | 630 | Aluminum Bronze | 9.0 – 11.0 | 78.0D | 2.0 – 4.0 | 1.50 | 4.0 – 5.5 | — | 0.25 max | — | — | 0.20 max | — |

| C64200 | 642 | Aluminum Silicon Bronze | 6.3 – 7.6 | 88.65D | 0.30 | 0.10 | 0.25 | — | 1.50 – 2.20E | 0.50 | 0.05 | 0.20 max | 0.15 |

| C65100 | 651 | Silicon Bronze | — | 96.0D | 0.80 | 0.70 | — | — | 0.8 – 2.0 | 1.50 | 0.05 | — | — |

| C65500 | 655 | Silicon Bronze | — | 94.8D | 0.80 | 1.50 | 0.60 | — | 2.8 – 3.8 | 1.50 | 0.05 | — | — |

| C66100 | 661 | Silicon Bronze | 0.25 max | 94.0D | 0.25 | 1.50 | — | — | 2.8 – 3.5 | 1.50 | 0.20 – 0.80 | — | — |

| C67500 | 675 | Manganese Bronze | — | 57.0 – 60.0 | 0.8 – 2.0 | 0.05 – 0.50 | — | — | — | balance | 0.20 | 0.50 – 1.50 | — |

| C71000 | 710 | Cupro Nickel | — | 74.0D | 0.60 | 1.00 | 19.0 – 23.0C | — | 1.00 | 0.05 | — | — | |

| C71500 | 715 | Cupro Nickel | — | 65.0D | 0.40 – 0.70 | 1.00 | 29.0 – 33.0C | — | — | 1.00 | 0.05 | — | — |

Nickel and Nickel base Alloys

| Composition, % Nickel and Nickel Base Alloys | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| UNS Designation | Alloy | General Name | Aluminum | Carbon, max | Chromium | CopperA | Iron, max | Manganese, max | NickelA | Phosphorus, max | Silicon, max | Titanium | Cobalt, max | Molybdenum | Sulfur, max | Vanadium | Tungsten |

| N10001 | 335 | Ni-Mo | — | 0.05 | 1.00 max | — | 4.00 – 6.00 | 1.00 | balance | 0.025 | 1.00 | — | 2.50 | 26.0 – 30.0 | 0.030 | 0.20 – 0.40 | — |

| N10276 | 276 | Ni-Mo-Cr | — | 0.02 | 14.5 – 16.5 | — | 4.00 – 7.00 | 1.00 | balance | 0.040 | 0.08 | — | 2.50 | 15.0 – 17.0 | 0.030 | 0.35 max | 3.0 – 4.5 |

| N04400 | 400 | Ni-Cu Class A | — | 0.30 | — | balance | 2.50 | 2.00 | 63.0 – 70.0 | — | 0.50 | — | B | — | 0.024 | — | — |

| N04405 | 405 | Ni-Cu Class B | — | 0.30 | — | balance | 2.50 | 2.00 | 63.0 – 70.0 | — | 0.50 | — | B | — | 0.025 – 0.060 | — | — |

| N05500 | 500 | Ni-Cu-Al | 2.30 – 3.15 | 0.25 | — | balance | 2.00 | 1.50 | 63.0 – 70.0 | 0.015 | 0.50 | 0.35 – 0.85 | B | — | 0.010 | — | — |

| N06059 | 59 | Ni-Cu-Mo | 0.10 – 0.40 | 0.010 max | 22.0 – 24.0 | 0.50 max | 1.50 | 0.50 | balance | 0.015 | 0.10 | — | 0.30 | 15.0 – 16.5 | 0.010 | — | — |

| N06625 | 625C | Ni-Cr-No-Cb | 0.40 max | 0.010 max | 20.0 – 23.0 | — | 5.00 | 0.50 | 58.0 min | 0.040 | 0.50 | 0.40 max | 1.00 | 8.0 – 10.0 | 0.015 | — | 3.2 – 4.2 |

| N06686 | 686 | Ni-Cr-Mo-W | — | 0.010 max | 19.0 – 23.0 | — | 5.00 | 0.50 | balance | — | 0.08 | 0.02 – 0.25 | — | 15.0 – 17.0 | 0.02 | — | 3.0 – 4.4 |

Aluminum Base Alloys

| Composition, % Aluminum Base Alloys | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| UNS Designation | Alloy | General Name | AluminumB | Chromium | Copper | Iron, max | Manganese, max | Silicon, max | Titanium, max | Zinc, max | Magnesium | Other Elements, max | |

| Each | Total | ||||||||||||

| A92024 | 2024 | Aluminum 2024 | balance | 0.10 max | 3.80 – 4.90 | 0.50 | 0.30 – 0.90 | 0.50 | 0.15C | 0.25 | 1.20 – 1.80 | 0.05 | 0.15 |

| A96061 | 6061 | Aluminum 6061 | balance | 0.04 – 0.35 | 0.15- 0.40 | 0.70 | 0.15 | 0.40 – 0.80 | 0.15 | 0.25 | 0.80 – 1.20 | 0.05 | 0.15 |

| A97075 | 7075 | Aluminum 7075 | balance | 0.18 – 0.35 | 1.20 – 2.00 | 0.50 | 0.30 | 0.40 | 0.20D | 5.10 – 6.10 | 2.10 – 2.90 | 0.05 | 0.15 |

Titanium and Titanium Base Alloys

| Composition, % Titanium and Titanium Base Alloys | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| UNS Designation | Alloy | General Name | Aluminum | Carbon | Iron | Titanium | Hydrogen | Nitrogen | Oxygen | Palladium | Vanadium | Chromium | Molybdenum | Zirconium |

| R50250 | 1 | Titanium Grade 1 | — | 0.10 | 0.20 | balance | 0.0125 | 0.05 | 0.18 | — | — | — | — | — |

| R50400 | 2 | Titanium Grade 2 | — | 0.10 | 0.30 | balance | 0.0125 | 0.05 | 0.25 | — | — | — | — | — |

| R50700 | 4 | Titanium Grade 4 | — | 0.10 | 0.50 | balance | 0.0125 | 0.07 | 0.40 | — | — | — | — | — |

| R56400 | 5C | Titanium grade 5C | 5.50 – 6.75 | 0.10 | 0.40 | balance | 0.0125 | 0.05 | 0.20 | 3.50 – 4.50 | ||||

| R54601 | 23 | Titanium Ti-5Al-4V ELI | 5.50 – 6.50 | 0.08 | 0.25 | balance | 0.0125 | 0.05 | 0.13 | — | 3.50 – 4.50 | — | — | — |

| R52400 | 7 | Titanium Grade 7 | — | 0.10 | 0.30 | balance | 0.0125 | 0.05 | 0.25 | 0.12 – 0.25 | — | — | — | — |

| R58640 | 19 | Titanium Ti-28-6-44 | 3.00 – 4.00 | 0.05 | 0.30 | balance | 0.0200 | 0.03 | 0.12 | 0.10D | 7.50 – 8.50 | 5.50 – 6.50 | 3.50 – 4.50 | 3.50 – 4.50 |

| R55111 | 32 | Titanium Ti-5-1-1-1 | 4.50 – 5.50 | 0.08 | 0.25 | balance | 0.0125 | 0.03 | 0.11 | — | 0.60 – 1.40 | — | 0.60 – 1.20 | |

ASTM F468 Bolts Mechanical Properties

| Alloy Group | Condition | Marking | Diameter Range | Tensile, ksi | Yield, ksi min | Rockwell Hardness |

|---|---|---|---|---|---|---|

| 1 | AF | F468A | 1/4 to 1-1/2 | 65 to 85 | 20 | B85 max |

| A | F468B | 1/4 to 1-1/2 | 75 to 100 | 30 | B65 to 95 | |

| CW1 | F468C | 1/4 to 5/8 | 100 to 150 | 65 | B95 to C32 | |

| CW2 | F468D | 3/4 to 1-1/2 | 85 to 140 | 45 | B80 to C32 | |

| 2 | AF | F468E | 1/4 to 1-1/2 | 65 to 85 | 20 | B85 max |

| A | F468F | 1/4 to 1-1/2 | 75 to 100 | 30 | B65 to 95 | |

| CW1 | F468G | 1/4 to 5/8 | 100 to 150 | 65 | B95 to C32 | |

| CW2 | F468H | 3/4 to 1-1/2 | 85 to 140 | 45 | B80 to C32 |

ASTM F468 Bolt Torque Chart

| BOLT DIA | Torque FT-LBS | ||

|---|---|---|---|

| 30% Initial Torque | 70% Torque | 100% Final Torque | |

| 1/2 | 16 | 36 | 52 |

| 9/16 | 23 | 53 | 75 |

| 5/8 | 31 | 73 | 104 |

| 3/4 | 55 | 129 | 184 |

| 7/8 | 71 | 166 | 237 |

| 1 | 107 | 249 | 356 |

| 1.1/8 | 127 | 297 | 424 |

| 1.1/4 | 179 | 417 | 596 |

| 1.3/8 | 186 | 435 | 622 |

| 1.1/2 | 246 | 574 | 821 |

| 1.9/16 | 168 | 392 | 560 |

| 1.5/8 | 191 | 445 | 636 |

| 1.3/4 | 240 | 561 | 801 |

| 1.7/8 | 298 | 696 | 994 |

| 2 | 366 | 853 | 1219 |

| 2.1/4 | 529 | 1234 | 1762 |

| 2.1/2 | 733 | 1709 | 2442 |

| 2.3/4 | 986 | 2300 | 3285 |

| 3 | 1289 | 3008 | 4297 |

| BOLT DIA | Torque Nm | ||

|---|---|---|---|

| 30% Initial Torque | 70% Torque | 100% Final Torque | |

| 1/2 | 22 | 49 | 71 |

| 9/16 | 31 | 72 | 102 |

| 5/8 | 42 | 99 | 141 |

| 3/4 | 75 | 175 | 249 |

| 7/8 | 96 | 225 | 321 |

| 1 | 145 | 338 | 483 |

| 1.1/8 | 172 | 403 | 575 |

| 1.1/4 | 243 | 565 | 808 |

| 1.3/8 | 252 | 590 | 843 |

| 1.1/2 | 334 | 778 | 1113 |

| 1.9/16 | 228 | 531 | 759 |

| 1.5/8 | 259 | 603 | 862 |

| 1.3/4 | 325 | 761 | 1086 |

| 1.7/8 | 404 | 944 | 1348 |

| 2 | 496 | 1157 | 1653 |

| 2.1/4 | 717 | 1673 | 2389 |

| 2.1/2 | 994 | 2317 | 3311 |

| 2.3/4 | 1337 | 3118 | 4454 |

| 3 | 1748 | 4078 | 5826 |

ASME SF468 Material Applications

- Construction, Mining, and Shipbuilding: Used in marine structures and mining equipment where salt spray and high humidity require long-lasting, corrosion-resistant fastening solutions.

- Oil & Gas and Refineries: Critical for offshore platforms and refinery infrastructure exposed to volatile chemicals and harsh weather conditions.

- Sugar & Food Processing: Employed in machinery where hygiene and resistance to organic acids are vital to prevent contamination.

- Chemicals and Fertilizers: Essential for equipment handling highly corrosive substances that would rapidly degrade carbon steel.

- Pharmaceuticals: Used in cleanroom equipment and processing tanks where non-reactive material properties are required.

- Water Treatment: Ideal for desalination plants and wastewater facilities to resist the corrosive effects of treated and untreated water.

- Heat Exchangers: Integrated into thermal management systems due to the excellent thermal conductivity and corrosion resistance of copper and nickel alloys.

- Paper & Pulp: High resistance to the bleaching agents and processing chemicals used in pulp manufacturing.

- Dairy: Utilized in food-grade processing lines where frequent sanitation and moisture resistance are mandatory.

ASTM F594 Nuts Price In India

| Product Description | Price (USD) | Price (INR Approx.) | Unit |

|---|---|---|---|

| ASTM F468 Heavy Hex Bolts | $0.01 – $0.05 | ₹0.85 – ₹4.20 | Per Piece |

| ASTM F468 Hexagonal Bolt | $0.10 – $0.30 | ₹8.40 – ₹25.00 | Per Piece |

| ASTM F468 Hex Head Bolt | $1.50 – $2.00 | ₹125.00 – ₹167.00 | Per Piece |

| ASTM F468 Stud Bolts | $1.50 – $2.00 | ₹125.00 – ₹167.00 | Per Piece |

| ASTM F468 Shoulder Bolt | $0.10 – $1.20 | ₹8.40 – ₹100.00 | Per Piece |

| ASTM F468 U Bolts (High Tensile) | $0.01 – $0.10 | ₹0.85 – ₹8.40 | Per Piece |

| F568 Hanger Bolt | $0.05 – $0.10 | ₹4.20 – ₹8.40 | Per Piece |

| ASTM F468 Hexagon Nut | $0.15 – $0.50 | ₹12.50 – ₹42.00 | Per Piece |

| ASTM F468 Hexagon Thin Nuts (All Sizes) | $0.10 – $0.30 | ₹8.40 – ₹25.00 | Per Piece |

Note: Please note that this is an approximate cost for ASTM F468 Bolts in India. Market fluctuations in raw material prices (like Nickel or Copper) will impact the final cost. For a formal ASTM F468 Stud price list and bulk discounts, please contact our sales team directly.

Related Products

We maintain ready stock of ASTM F468 Hex Head Bolts, ASTM F468 Heavy Hex Bolts, ASTM F468 Square Head Bolts, ASTM F468 Flange Bolts, ASTM F468 Eye Bolts & ASME SF468 U Bolts. Get in touch with us with your requirement for a quick quote.

Request a Quote