Garde B7 fastener is a very suitable choice for the petroleum and chemical industries. They come with the ASTM standard and are designed for high temperature and high pressure applications like pressure vessels, valves, flanges, and fittings. They are also available in different standards such as UNC thread pitches, diameters over one inch typically use 8 threads per inch (tpi) for traditional uses.

For a quick quote on A193 Grade B7 Bolts, reach out to us at Contact Us page.

ASTM A193 B7 Bolts, ASTM A193 Grade B7 Stud Bolts, B7 Fasteners and Nuts, A193 Gr. B7 Threaded Rod Manufacturer and Supplier

Jade Special Metals is a company that manufactures and supplies ASTM A193 B7 Bolts, ASTM A193 Grade B7 Stud Bolts, A193 B7 Fasteners and Nuts, and A193 Gr.1 B7 Threaded Rod. We make available these quality fasteners to our customers worldwide and serve many sectors in the world. The most utilized type of A193 bolting material is Grade B7 which is used in several industries. They are manufactured using tough chromium-molybdenum steel that is heat-treated during which they are expected to have the requisite mechanical properties as high tensile strength and great ductility. This is a type of treatment that involves quenching and tempering of bolts to a minimum temperature of 1150o F (620o C). This is done to ensure that the material fits within the limits as stipulated, with a maximum Rockwell Hardness of 35 HRC.

Looking to buy Alloy Steel Fasteners?

Check Carbon Steel Fasteners Price List in India

Bolts Weight Chart

Table of Content

- Types of A193 Grade B7 Fasteners

- ASTM A193 Grade B7 Stainless Steel Bolts Specification

- ASTM A193 Grade B7 Fasteners Chemical Composition

- ASTM A193 Grade B7 Bolts Mechanical Properties

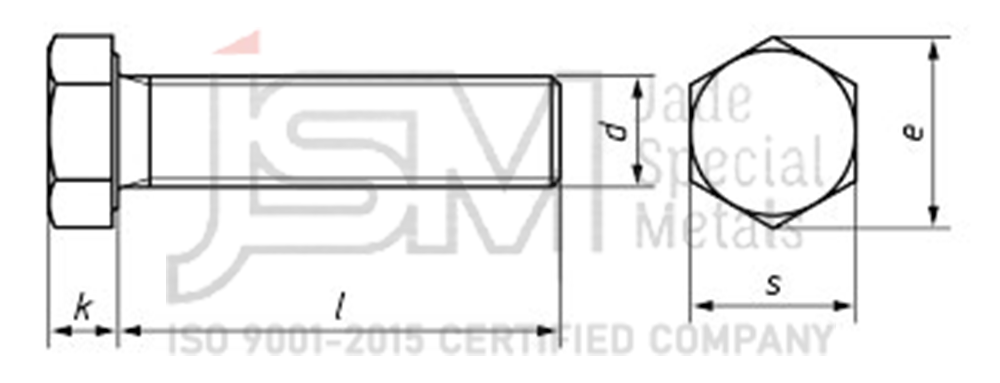

- SA193 Grade B7 Heavy Hex Bolts Dimension

- Dimension of ASTM A193 Grade B7 Bolts

- A193 B7 Studs Size Chart

- ASTM A193 Grade B7 Torque Chart

- ASTM A193 Gr B7 Stud Bolt Weight

- ASTM A193 B7 Bolts Inventory

- Applications of ASTM A193 B7 Bolts

Types of A193 Grade B7 Fasteners

A193 B7 Stud Bolts

A193 B7 Hex Bolts

A193 B7 Anchor Bolts

A193 B7 Threaded Rods

A193 B7 Socket Head Cap Screws

A193 B7 Heavy Hex Bolts

A193 B7 U-Bolts

A193 B7 Washers

ASTM A193 Grade B7 Stainless Steel Bolts Specification

| Specification | Details |

|---|---|

| A193 Grade B7 Bolts Dimensions Standards | ASME B18.2.1, B18.3 |

| Threads Configuration | ASME B1.1 2A/3A Inch Unified Threads and B1.13M 6h Metric Coarse Threads |

| A193 Grade B7 Studs Certification | Dual Certified As per ASTM & ASME Codes |

| Additional Certifications | PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified |

| A193 Grade B7 Threaded Rod Mandatory Requirements | Free from Mercury & Radioactive Contamination |

| Additional Requirements | NACE MR0103 / MR0175 / ISO 15156 Compliance |

ASTM A193 Grade B7 Fasteners Chemical Composition

| Chemical composition | C. | Mn. | Si. | P. | S. | Cr. | Ni. | Mo. | V. | Ti. |

|---|---|---|---|---|---|---|---|---|---|---|

| B7 | 0.37—0.49 | 0.65—1.10 | 0.15—0.35 | 0.035 max. | 0.04 max. | 0.75—1.20 | — | 0.15—0.25 | — | — |

ASTM A193 Grade B7 Bolts Mechanical Properties

| Class | Diameter, [mm] | Minimum Tempering Temperature, °C | Tensile Strength, min, MPa | Yield Strength, min, 0.2 % offset, MPa | Elongation in 4D, min, % | Reduction of Area, min, % | Hardness, max |

|---|---|---|---|---|---|---|---|

| B7 Chromium-molybdenum | M64 and under | 593 | 860 | 720 | 16 | 50 | 321 HB or 35 HRC |

| over M64 to M100 | 593 | 795 | 655 | 16 | 50 | 321 HB or 35 HRC | |

| over M100 to M180 | 593 | 690 | 515 | 18 | 50 | 321 HB or 35 HRC |

SA193 Grade B7 Heavy Hex Bolts Dimension

| NOMINAL SIZE (D) | BODY DIAMETER | HEAD THICKNEASTM A193 | ACROASTM A193 THE FLATS | ACROASTM A193 CORNERS | ||||

|---|---|---|---|---|---|---|---|---|

| D (MAX) | D (MIN) | H (MAX) | H (MIN) | F (MAX) | F (MIN) | C (MAX) | C (MIN) | |

| m10 | 10.00 | 9.78 | 6.63 | 6.17 | 17.00 | 15.73 | 18.48 | 17.77 |

| m14 | 14.00 | 13.73 | 9.09 | 8.51 | 22.00 | 20.67 | 24.25 | 23.35 |

| m80 | 80.00 | 79.26 | 51.58 | 48.42 | 115.00 | 111.00 | 132.72 | 126.54 |

| m16 | 16.00 | 15.73 | 10.32 | 9.68 | 24.00 | 23.67 | 27.71 | 26.75 |

| m20 | 20.00 | 19.67 | 12.88 | 12.12 | 30.00 | 29.16 | 34.64 | 32.95 |

| m48 | 48.00 | 47.38 | 31.07 | 28.93 | 75.00 | 72.60 | 86.60 | 82.76 |

| m24 | 24.00 | 23.67 | 15.44 | 14.56 | 36.00 | 35.00 | 41.57 | 39.55 |

| m30 | 30.00 | 29.67 | 19.48 | 17.92 | 46.00 | 45.00 | 53.12 | 50.85 |

| m36 | 36.00 | 35.61 | 23.38 | 21.63 | 55.00 | 53.80 | 63.51 | 60.79 |

| m42 | 42.00 | 41.38 | 26.97 | 25.03 | 65.00 | 62.90 | 75.06 | 71.71 |

| m56 | 56.00 | 55.26 | 36.2 | 33.80 | 85.00 | 82.20 | 98.15 | 93.71 |

| m64 | 64.00 | 63.26 | 41.32 | 38.68 | 95.00 | 91.80 | 109.70 | 104.65 |

| m72 | 72.00 | 71.26 | 46.45 | 43.55 | 105.00 | 101.40 | 121.24 | 115.60 |

| m12 | 12.00 | 11.73 | 7.76 | 4.24 | 19.00 | 17.73 | 20.78 | 20.03 |

| m90 | 90.00 | 89.13 | 57.74 | 54.26 | 130.00 | 125.50 | 150.11 | 143.07 |

| m100 | 90.00 | 99.13 | 63.9 | 60.10 | 145.00 | 140.00 | 167.43 | 159.60 |

Dimension of ASTM A193 Grade B7 Bolts

| Diameter (D) | Body Diameter (D) | Across the Flats (F) | Across the Corners © | Head Height (H) | Thread Lengths (T) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| MAX | MIN | MAX | MIN | MAX | MIN | MAX | MIN | < 6” | > 6” | |

| 1 | 1.022 | 0.976 | 1.625 | 1.575 | 1.876 | 1.796 | 0.7 | 0.591 | 2.25 | 2.5 |

| 5/8 | 0.642 | 0.605 | 1.062 | 1.031 | 1.227 | 1.175 | 0.444 | 0.378 | 1.5 | 1.75 |

| 3/4 | 0.768 | 0.729 | 1.25 | 1.212 | 1.443 | 1.383 | 0.524 | 0.455 | 1.75 | 2 |

| 1/2 | 0.515 | 0.482 | 0.875 | 0.85 | 1.01 | 0.969 | 0.364 | 0.302 | 1.25 | 1.5 |

| 7/8 | 0.895 | 0.852 | 1.438 | 1.394 | 1.66 | 1.589 | 0.604 | 0.531 | 2 | 2.25 |

| 1 1/8 | 1.149 | 1.098 | 1.812 | 1.756 | 2.093 | 2.002 | 0.78 | 0.658 | 2.5 | 2.75 |

| 1 1/4 | 1.277 | 1.223 | 2 | 1.938 | 2.309 | 2.209 | 0.876 | 0.749 | 2.75 | 3 |

| 1 3/4 | 1.785 | 1.716 | 2.75 | 2.662 | 3.175 | 3.035 | 1.196 | 1.054 | 3.75 | 4 |

| 1 3/8 | 1.404 | 1.345 | 2.188 | 2.119 | 2.526 | 2.416 | 0.94 | 0.81 | 3 | 3.25 |

| 1 1/2 | 1.531 | 1.47 | 2.375 | 2.3 | 2.742 | 2.622 | 1.036 | 0.902 | 3.25 | 3.5 |

| 2 3/4 | 2.827 | 2.711 | 4.25 | 4.112 | 4.907 | 4.688 | 1.869 | 1.632 | 5.75 | 6 |

| 2 | 2.039 | 1.964 | 3.125 | 3.025 | 3.608 | 3.449 | 1.388 | 1.175 | 4.25 | 4.5 |

| 2 1/4 | 2.305 | 2.214 | 3.5 | 3.388 | 4.041 | 3.862 | 1.548 | 1.327 | 4.75 | 5 |

| 2 1/2 | 2.559 | 2.461 | 3.875 | 3.75 | 4.474 | 4.275 | 1.708 | 1.479 | 5.25 | 5.5 |

| 3 | 3.081 | 2.961 | 4.625 | 4.475 | 5.34 | 5.102 | 2.06 | 1.815 | 6.25 | 6. |

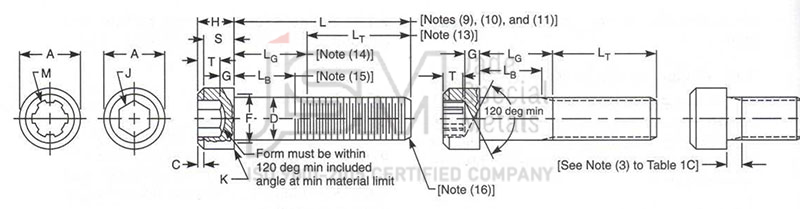

A193 B7 Studs Size Chart

Check the weight and dimensions of A193 B7 Hex Bolts and ASTM A193 Grade B7 Stud Bolts

| Nominal Basic | Size or Screw | Body | D Diameter | Head | A Diameter | Head | H Height | $ Head Side Height | J Hex Socket Size | T Key Engagmt | G Wall Thkns | K Chamfer or Radius |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Diameter | Max | Min | Max | Min | Max | Min | Max | Nominal | Min | Min | Max | |

| 0 | 0.0600 | 0.0600 | 0.0568 | 0.096 | 0.091 | 0.060 | 0.057 | 0.054 | 0.050 | 0.025 | 0.020 | 0.003 |

| 1 | 0.0730 | 0.0730 | 0.0695 | 0.118 | 0.112 | 0.073 | 0.070 | 0.066 | 1/16 0.062 | 0.031 | 0.025 | 0.003 |

| 2 | 0.0860 | 0.0860 | 0.0822 | 0.140 | 0.134 | 0.086 | 0.083 | 0.077 | 5/64 0.078 | 0.038 | 0.029 | 0.003 |

| 3 | 0.0990 | 0.0990 | 0.0949 | 0.161 | 0.154 | 0.099 | 0.095 | 0.089 | 5/64 0.078 | 0.044 | 0.034 | 0.003 |

| 4 | 0.1120 | 0.1120 | 0.1075 | 0.183 | 0.176 | 0.112 | 0.108 | 0.101 | 3/32 0.094 | 0.051 | 0.038 | 0.005 |

| 5 | 0.1250 | 0.1250 | 0.1202 | 0.205 | 0.198 | 0.125 | 0.121 | 0.112 | 3/32 0.094 | 0.057 | 0.043 | 0.005 |

| 6 | 0.1380 | 0.1380 | 0.1329 | 0.226 | 0.218 | 0.138 | 0.134 | 0.124 | 7/64 0.109 | 0.064 | 0.047 | 0.005 |

| 8 | 0.1640 | 0.1640 | 0.1585 | 0.270 | 0.262 | 0.164 | 0.159 | 0.148 | 9/64 0.141 | 0.077 | 0.056 | 0.005 |

| 10 | 0.1900 | 0.1900 | 0.1840 | 0.312 | 0.303 | 0.190 | 0.185 | 0.171 | 5/32 0.156 | 0.090 | 0.065 | 0.005 |

| 1/4 | 0.2500 | 0.2500 | 0.2435 | 0.375 | 0.365 | 0.250 | 0.244 | 0.225 | 3/16 0.188 | 0.120 | 0.095 | 0.008 |

| 5/16 | 0.3125 | 0.3125 | 0.3053 | 0.469 | 0.457 | 0.312 | 0.306 | 0.281 | 1/4 0.250 | 0.151 | 0.119 | 0.008 |

| 3/8 | 0.3750 | 0.3750 | 0.3678 | 0.562 | 0.550 | 0.375 | 0.368 | 0.337 | 5/16 0.312 | 0.182 | 0.143 | 0.008 |

| 7/16 | 0.4375 | 0.4375 | 0.4294 | 0.656 | 0.642 | 0.438 | 0.430 | 0.394 | 3/8 0.375 | 0.213 | 0.166 | 0.010 |

| 1/2 | 0.5000 | 0.5000 | 0.4919 | 0.750 | 0.735 | 0.500 | 0.492 | 0.450 | 3/8 0.375 | 0.245 | 0.190 | 0.010 |

| 5/8 | 0.6250 | 0.6250 | 0.6163 | 0.938 | 0.921 | 0.625 | 0.616 | 0.562 | 1/2 0.500 | 0.307 | 0.238 | 0.010 |

| 3/4 | 0.7500 | 0.7500 | 0.7406 | 1.125 | 1.107 | 0.750 | 0.740 | 0.675 | 5/8 0.625 | 0.370 | 0.285 | 0.010 |

| 7/8 | 0.8750 | 0.8750 | 0.8647 | 1.312 | 1.293 | 0.875 | 0.864 | 0.787 | 3/4 0.750 | 0.432 | 0.333 | 0.015 |

| 1 | 1.0000 | 1.0000 | 0.9886 | 1.500 | 1.479 | 1.000 | 0.988 | 0.900 | 3/4 0.750 | 0.495 | 0.380 | 0.015 |

| See Notes | 1 | 2,15 | 3 | 4 | 21 | 6 |

“Contact Jade Special Metals today with your requirement for ASTM A193 B7 Bolts. We assure you of the best quote.

ASTM A193 Grade B7 Torque Chart

| A193 Grade B7 Bolts Nominal Diameter (in) | Threads (in) | Torque ft-lb (Dry) | Torque ft-lb (Lubricated) |

|---|---|---|---|

| 3/4″ | 10 | 203 | 152 |

| 16 | 226 | 170 | |

| 5/16″ | 18 | 13.2 | 10.0 |

| 24 | 14.7 | 11.0 | |

| 3/8″ | 16 | 23.5 | 17.7 |

| 24 | 26.6 | 19.9 | |

| 7/16″ | 16 | 37.6 | 28.2 |

| 24 | 42.0 | 31.5 | |

| 1/2″ | 13 | 57.4 | 43.0 |

| 20 | 64.7 | 48.5 | |

| 9/16″ | 12 | 82.7 | 62.1 |

| 18 | 92.3 | 69.2 | |

| 1/4″ | 20 | 6.5 | 4.8 |

| 28 | 7.4 | 5.5 | |

| 7/8″ | 9 | 326 | 245 |

| 14 | 361 | 270 | |

| 1″ | 8 | 490 | 368 |

| 14 | 549 | 412 | |

| 1-1/4″ | 7 | 853 | 639 |

| 12 | 944 | 708 | |

| 1-1/2″ | 6 | 1484 | 639 |

| 12 | 1669 | 1252 | |

| 1/4″ | 20 | 7.4 | 5.5 |

| 28 | 8.4 | 6.3 | |

| 5/8″ | 11 | 114.2 | 85.7 |

| 18 | 129.3 | 97.0 | |

| 5/16″ | 18 | 15.1 | 11.4 |

| 24 | 16.8 | 12.6 | |

| 3/8″ | 16 | 26.9 | 20.2 |

| 24 | 30.4 | 22.8 | |

| 7/16″ | 14 | 43.0 | 32.3 |

| 20 | 48.0 | 36.0 | |

| 1/2″ | 13 | 65.6 | 49.1 |

| 20 | 73.9 | 55.4 | |

| 9/16″ | 12 | 94.5 | 71.0 |

| 18 | 105.5 | 79.1 | |

| 5/8″ | 11 | 130.5 | 97.9 |

| 18 | 147.8 | 110.9 | |

| 3/4″ | 10 | 232 | 174 |

| 16 | 258 | 194 | |

| 7/8″ | 9 | 373 | 280 |

| 14 | 412 | 309 | |

| 1-1/4″ | 7 | 975 | 730 |

| 12 | 1079 | 809 | |

| 1-1/2″ | 6 | 1696 | 1271 |

| 12 | 1908 | 1430 | |

| 1″ | 8 | 560 | 420 |

| 14 | 628 | 471 |

| A193 Grade B7 Bolts Size | TPI | Proof Load (lbs) | Clamp Load (lbs) | Tightening Torque (ft lbs) Galv + Wax |

Tightening Torque (ft lbs) Galv |

Tightening Torque (ft lbs) Plain |

|---|---|---|---|---|---|---|

| 1/4″ | 20 | 3,350 | 2,513 | 5 | 13 | 10 |

| 9/16″ | 12 | 19,100 | 14,325 | 67 | 168 | 134 |

| 3/8″ | 16 | 8,150 | 6,113 | 19 | 48 | 38 |

| 7/16″ | 14 | 11,150 | 8,363 | 30 | 76 | 61 |

| 5/16″ | 18 | 5,500 | 4,125 | 11 | 27 | 21 |

| 1/2″ | 13 | 14,900 | 11,175 | 47 | 116 | 93 |

| 5/8″ | 11 | 23,750 | 17,813 | 93 | 232 | 186 |

| 1″ | 8 | 63,650 | 47,738 | 398 | 995 | 796 |

| 3/4″ | 10 | 35,050 | 26,288 | 164 | 411 | 329 |

| 7/8″ | 9 | 48,500 | 36,375 | 265 | 663 | 530 |

ASTM A193 Gr B7 Stud Bolt Weight

| Length | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 |

|---|---|---|---|---|---|

| 3″ | 0.13 | 0.3 | 0.55 | 0.9 | 1.33 |

| 3-1/4″ | 0.14 | 0.33 | 0.6 | 0.97 | 1.44 |

| 3-1/2″ | 0.15 | 0.35 | 0.65 | 1.05 | 1.55 |

| 4″ | 0.17 | 0.4 | 0.74 | 1.2 | 1.77 |

| 4-1/4″ | 0.18 | 0.43 | 0.79 | 1.27 | 1.88 |

| 4-1/2″ | 0.19 | 0.45 | 0.83 | 1.35 | 1.99 |

| 5″ | 0.22 | 0.51 | 0.93 | 1.5 | 2.22 |

| 5-1/4″ | 0.23 | 0.53 | 0.97 | 1.58 | 2.33 |

| 5-1/2″ | 0.24 | 0.56 | 1.02 | 1.65 | 2.44 |

| 6″ | 0.26 | 0.61 | 1.11 | 1.8 | 2.66 |

| 6-1/4″ | 0.27 | 0.63 | 1.16 | 1.88 | 2.77 |

| 6-1/2″ | 0.28 | 0.66 | 1.2 | 1.95 | 2.88 |

| 7″ | 0.3 | 0.71 | 1.3 | 2.1 | 3.1 |

| 7-1/4″ | 0.31 | 0.73 | 1.34 | 2.18 | 3.21 |

| 7-1/2″ | 0.33 | 0.76 | 1.39 | 2.25 | 3.33 |

Applications of ASTM A193 B7 Bolts

- Oil & Gas

- Petrochemical & Refining

- Power Generation

- Heavy Construction & Engineering

- Manufacturing

Related Products

FAQ’s About ASTM A193 B7 Bolts

What is A193 B7 bolt specification?

The ASTM A193 B7 specification defines a high-tensile fastener made from heat-treated chromium-molybdenum (Cr-Mo) alloy steel (typically AISI 4140). It requires a minimum tensile strength of 125 ksi, a minimum yield strength of 105 ksi, and has a maximum hardness of 35 HRC, making it ideal for high-pressure and high-temperature service.

What is ASTM A193 B7 material equivalent to?

ASTM A193 Grade B7M bolts and studs are identical in chemistry to Grade B7 (quenched and tempered medium carbon alloy steel), but have lower strength requirements and require 100% hardness testing of all fasteners manufactured in the lot.

What is the difference between A193 B7 and B7M?

A193 B7M has the same chemical composition as B7 but is manufactured to have lower tensile strength and hardness. B7M bolts are specifically intended for use in corrosive or sour gas (H₂S) service and require 100% hardness testing on all fasteners in a lot to ensure they meet the lower, more controlled hardness limits.

How many threads per inch is A193 B7?

The thread pitch depends on the bolt’s diameter. For traditional applications, A193 B7 bolts typically follow the Unified National Coarse (UNC) thread series. A common rule is that for diameters over 1 inch, the specification is 8 threads per inch (8-TPI).

Is A193 B7 bolt material carbon steel?

No. A193 B7 is an alloy steel, not a carbon steel. The addition of chromium and molybdenum gives it superior strength and temperature resistance compared to standard carbon steels. It achieves its high strength through a specific quenching and tempering heat treatment process.

Do B7 bolts rust?

Yes. Since A193 B7 is an alloy steel and not a stainless steel, it will rust if exposed to moisture or corrosive environments. To prevent this, B7 bolts are often supplied with a protective coating, such as PTFE (Teflon/Xylan), Zinc Plating, or Hot-Dip Galvanizing, especially when used in outdoor, marine, or chemical plant applications.