Inconel Sheets and Inconel Plate have a number of major mechanical and chemical strengths. They have excellent corrosion protection, and they give superior protection against oxidation and corrosive substances such as acids, salts and high temperature gases that make them the best in situations where corrosion is a significant factor of operation. Moreover, they demonstrate high weldability so that using the materials, it is possible to make the joints strong and durable because there is no necessity to impair the properties of the alloy with the help of traditional methods such as Gas Tungsten Arc Welding (GTAW) or Gas Metal Arc Welding (GMAW). Finally, the Inconel materials, although more powerful and tough, are good workable which means that they can still be cut, shaped and molded using the conventional processes of intricate fabrication.

Inconel Sheets, Plates, and Coils are essential parts of the challenging sectors, such as aerospace, chemical processing, marine engineering, and gas turbines since they are stronger, more resistant in terms of corrosion, and stable under high temperatures. Inconel alloy is also common in the aerospace industry where it is used in the most important engine parts, exhaust systems and structural parts that are required to withstand high temperatures. In the same manner, chemical processing plants depend on the superior corrosion strength of Inconel in the construction of reactors, vessels and piping systems. The alloy is also used in marine engineering, where the presence of saltwater is always a risk, such as valves, pumps, and shafts. Lastly, Inconel is relied on by gas turbines in blades, combustion chambers, etc. high-temperature components, guaranteeing more reliability and longer durability of these high-power machines.

Inconel Sheets Manufacturers, Incoloy Plate, Incoloy Sheets, Inconel® Alloy Sheets, Thin Incoloy Sheets, Inconel® Alloy Plates, Perforated Incoloy Sheets and Inconel Plate Suppliers in India

Jade Alloys is a well-known manufacturer, supplier, and exporter of high-performance Inconel / Incoloy Sheets & Plates that are widely used in different industries. The material has great importance due to the high level of corrosion resistance, durability and strength in high temperature and demanding environments.

To have dependable performance, Jade Alloys offers these sheets and plates in high grades, thicknesses, sizes, and also specifications which meet certain customer requirements. The materials are manufactured in a well-equipped facility whereby high quality raw materials are used which are acquired through reputed market suppliers and the use of the latest technology and equipment. Each and every product is produced with a very stringent compliance with most of the global and local standards of quality ensuring that the provided Inconel plates and sheets are a reliable option to a wide range of highly important applications.

Looking to buy Inconel Sheets & Plates?

Check Inconel Sheets & Plates Price in India

Weight Calculator

Incoloy Sheets & Plates Specifications

We provide Inconel Sheets & Plates according to various international standards. Below are the key specifications for these high-performance nickel alloys.

| Specifications | ASTM B168 / ASME SB168 |

|---|---|

| Dimensions | MSRR, AMS, BS, JIS, AISI, ASTM, GB, DIN, EN, etc |

| Size Range | Cold Rolled : 0.5-6.4 mm Hot Rolled : 3.0–10.0 mm |

| Thickness | 0.3 mm to 120 mm |

| Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

| International Standard | ASTM A480 ASTM A959 ASME IID EN ISO 9445 EN ISO 18286 EN 10051 EN 10088-1 ISO 15510 |

| Tolerances (width / thickness) | EN 10258/ DIN 59381 EN 10151 EN 10088 |

| Form | Sheet, Plate, Coil |

| Finish | Cold rolled sheet (CR) & Hot rolled plate (HR). |

| Hardness | Half Hard, Soft, Hard, Quarter Hard, Spring Hard |

| Value Added Service | Cladding, Heat Treatment, Annealed, Pickling, Polish, Rolling, Cutting, Bending, Forging, Minor Fabrication Etc. |

| Profiling | Plasma Plate Cutting Laser Plate Cutting Oxy-propane Flame Cutting |

| Grades | 600 / 601 / 625 / 718 / 800 / 825 |

Chemical Composition of Inconel Alloy Sheets & Plates

Knowledge of the Chemical Composition of Inconel Alloy Sheets and Plates is mandatory to the understanding of performance in high temperatures and corrosive conditions. The following table helps to identify the limiting concentrations of the elements of critical elements in each grade of the Inconel Sheets and the Incoloy Plate.

| Grade | Co | Mo | Fe | Cr | Nb | Ni | Ti | Mn | Al | Cu | Si | S | C | B | P |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inconel 600 | – | – | 6.0–10.0 | 14.0–17.0 | – | ≥72.0 (bal) | – | 1.0 max | – | 0.5 max | 0.5 max | 0.015 max | 0.15 max | – | – |

| Inconel 601 | – | – | bal | 21.0–25.0 | – | 58.0–63.0 | – | 1.0 max | 1.0–1.7 | – | 0.5 max | 0.015 max | 0.10 max | – | 0.05 max |

| Inconel 625 | 1.0 max | 8.0–10.0 | 5.0 max | 20.0–23.0 | 3.15–4.15 | 58.0 min | 0.4 max | 0.5 max | 0.4 max | – | 0.5 max | 0.015 max | 0.10 max | – | 0.015 max |

| Inconel 718 | 1.0 max | 2.8–3.3 | bal | 17.0–21.0 | 4.75–5.5 | 50.0–55.0 | 0.3–0.7 | 0.35 max | 0.2–0.8 | 0.2 max | 0.35 max | 0.015 max | 0.08 max | 0.006 max | 0.015 max |

| Incoloy 800 / 800H / 800HT | – | – | 39.5 min (bal) | 19.0–23.0 | – | 30.0–35.0 | 0.15–0.60 | 1.5 max | 0.15–0.60 | 0.75 max | 1.0 max | 0.015 max | 0.10 max | – | 0.03 max |

| Incoloy 825 | – | 2.5–3.5 | 22.0 min (bal) | 19.5–23.5 | – | 38.0–46.0 | 0.6–1.2 | 1.0 max | – | 1.5–3.0 | 0.5 max | 0.015 max | 0.05 max | – | 0.03 max |

Mechanical Properties of Inconel Plates & Sheets

The figures demonstrate the strength and durability of the Incoloy Sheets and the Inconel Plate products are very strong. Mechanical properties are critical metrics that are usually considered during the Inconel sheets and plates price.

| Grade | Tensile Strength (UTS) MPa | Yield Strength (0.2% YS) MPa | Elongation % | Hardness | Service Temperature |

|---|---|---|---|---|---|

| Inconel 600 | 550–690 | 240–310 | 30–45% | HRB 85 max / ~150 HB | Up to 1200°C |

| Inconel 601 | 620–760 | 275–310 | 30–45% | 150–180 HB | Up to 1250°C |

| Inconel 625 | 827–930 | 414–517 | 30–35% | 200–240 HB | Up to 980°C / 1090°C (solution annealed) |

| Inconel 718 | 1275–1380 | 1030–1100 | 12–20% | 330–380 HB / 36–44 HRC | Up to 700°C (high strength) |

| Incoloy 800 / 800H / 800HT | 520–620 | 205–275 | 30–45% | 150–200 HB | Up to 1100°C |

| Incoloy 825 | 690–760 | 275–350 | 30–45% | 150–200 HB | Up to 540°C |

Equivalent Grades of Inconel & Incoloy Sheets & Plates

To facilitate international trade and facilitate documentation, the following table gives the equivalent international standards of each alloy. It is worth noting that the right Inconel plate HS code requires depending on the product form and composition in question.

| Material / Grade | Werkstoff Nr. | UNS | BS | GOST | OR | JIS | EN | AFNOR |

|---|---|---|---|---|---|---|---|---|

| Inconel 600 Sheets & Plates | 2.4816 | N06600 | NA 13 | МНЖМц 28-2,5-1,5 | ЭИ868 | NCF 600 | NiCr15Fe | NC15FE11M |

| Inconel 601 Sheets & Plates | 2.4851 | N06601 | NA 49 | – | – | NCF 601 | NiCr23Fe | – |

| Inconel 625 Sheets & Plates | 2.4856 | N06625 | NA 21 | ХН75МБТЮ | ЭИ602 | NCF 625 | NiCr22Mo9Nb | NC22DNB4M |

| Inconel 718 Sheets & Plates | 2.4668 | N07718 | – | – | – | – | – | – |

| Incoloy 800 / 800H / 800HT Sheets & Plates | 1.4876 / 1.4958 / 1.4959 | N08800 / N08810 / N08811 | NA 15 | ЭИ670 | XH32T | NCF 800 | X10NiCrAlTi32-20 | Z8NC32-21 |

| Incoloy 825 Sheets & Plates | 2.4858 | N08825 | NA 16 | ЭП703 | XH38BT | NCF 825 | NiCr21Mo | NFE30C20DUM |

Inconel Sheets Sizes

Inconel Sheets and Inconel Plate are produced in various thicknesses and widths commonly using gauge as the measurement.

| Inconel Gauge Width and Length | Weight Lbs. per Sq. Ft. | Estimated Weight per Sheet |

|---|---|---|

| 7 ga. (.1874″) x 48 x 120 | 7.871 | 314.8 |

| 10 ga. (.135″) x 48 x 120 | 5.670 | 226.8 |

| 11 ga. (.120″) x 36 x 120 | 5.040 | 151.2 |

| 11 ga. (.120″) x 48 x 96 | 5.040 | 161.3 |

| 11 ga. (.120″) x 48 x 120 | 5.040 | 201.6 |

| 11 ga. (.120″) x 48 x 144 | 5.040 | 241.9 |

| 11 ga. (.120″) x 60 x 96 | 5.040 | 252.0 |

| 12 ga. (.105″) x 36 x 120 | 4.410 | 132.3 |

| 12 ga. (.105″) x 48 x 120 | 4.410 | 176.4 |

| 12 ga. (.105″) x 60 x 120 | 4.410 | 220.5 |

| 14 ga. (.075″) x 36 x 120 | 3.150 | 94.50 |

| 14 ga. (.075″) x 48 x 120 | 3.150 | 126.0 |

| 16 ga. (.060″) x 36 x 120 | 2.520 | 75.60 |

| 16 ga. (.060″) x 48 x 96 | 2.520 | 80.64 |

| 16 ga. (.060″) x 48 x 120 | 2.520 | 100.8 |

| 16 ga. (.060″) x 60 x 120 | 2.520 | 126.0 |

| 18 ga. (.048″) x 36 x 120 | 2.016 | 60.48 |

| 18 ga. (.048″) x 48 x 120 | 2.016 | 80.64 |

| 20 ga. (.036″) x 36 x 120 | 1.512 | 45.36 |

| 20 ga. (.036″) x 48 x 120 | 1.512 | 60.48 |

| 22 ga. (.030″) x 36 x 120 | 1.260 | 37.80 |

| 22 ga. (.030″) x 48 x 96 | 1.260 | 40.32 |

| 22 ga. (.030″) x 48 x 120 | 1.260 | 50.40 |

| 24 ga. (.024″) x 36 x 120 | 1.008 | 30.24 |

| 24 ga. (.024″) x 48 x 120 | 1.008 | 40.32 |

| 26 ga. (.018″) x 36 x 120 | .7560 | 22.68 |

| 26 ga. (.018″) x 48 x 120 | .7560 | 30.24 |

| 28 ga. (.015″) x 36 x 120 | .6300 | 18.90 |

For quick reference on material mass, use our Inconel plate weight calculator.

Types of Inconel Sheets & Plates

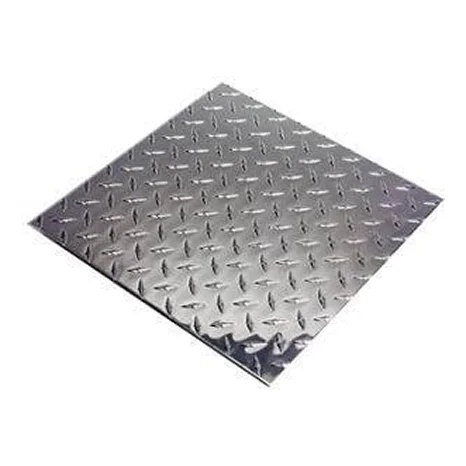

Inconel Chequered Plate

Inconel Circles

Inconel Coils

Inconel Flat

Inconel Foils

Inconel HR Sheets

Inconel Profile

Inconel Sheets Cut To Size

Inconel Slitting Coil

Inconel Strips

Inconel Ring

Thin Inconel Sheets

Inconel Alloy Cold Rolled Sheets

Inconel Alloy HR Strip

Inconel Blank

Inconel Checker Plate

Applications of Incoloy Sheets & Plates

Chemical Industry

Petrochemical Industry

Marine & Power Transmission Industry

Power Plants

Energy Industries

Furniture

Pharmaceutical Processing

Modern Architecture

Home Appliances

Water Waste Projects

Synthetic Fiber

Heat Exchanger

Fluid Piping

Dairy & Food Processing

Inconel Sheets & Plates Price in India

Inconel Sheets & Plates are highly applicable in the high temperature and corrosive conditions because of its high strength and durability. When comparing the price of Inconel sheets and plates or searching for reliable supplier of Inconel plate in India, one should look at the grade that will provide long lasting performance in stressful applications.

| Product | Price Range | Unit | FOB Price |

|---|---|---|---|

| Inconel HR Plates | US $800–3000 | Metric Ton | FOB Price |

| Hot Rolled Inconel Plates | US $605–629 | Metric Ton | FOB Price |

| Inconel Alloy Cold Rolled Sheets | US $800–4000 | Metric Ton | FOB Price |

| Inconel Alloy Plates | US $500–800 | Metric Ton | FOB Price |

| Inconel Alloy CR Sheets | US $560–670 | Ton | FOB Price |

| Inconel® Alloy HR Plates | US $500–900 | Ton | FOB Price |