ASTM A193 Grade fasteners are classified under the alloy steel and stainless steel fasteners to use in assemblies that work under high-pressure or temperature service and are critical to use in pressure vessels, valves, flanges, and fittings. The grade is also extensively used in a number of industries such as Wind farms, Sewage treatment plants, ships, and chemical construction works. On the one hand, the material is commonly supplied with National Coarse (UNC) thread-pitch; on the other hand, the conventional high-pressure usage is to designate 8 threads/in (tpi) when the fastener diameter is more than an inch.

ASTM A193 Grade B8 Specification

The A193 Grade B8 is the ASTM standard specification of high-tensile fasteners, which are made using 304 or 304L stainless steel. These bolts have been designed to serve demanding operation conditions, mostly in high temperature, high pressure service and other special purpose. The Grade B8, A193 alloy is chemically identical to the typical AISI 304 (18-8) alloy of stainless steel.

The specification classifies the material into two categories depending on its strength. Grade B8 Class 1 bolts are carbide solution treated and their maximum tensile strength is 75 ksi (515 Mpa), yield strength is 30 ksi (205 Mpa) and their hardness is 223 HBW at maximum. Grade B8 Class 2 bolts, in their turn, are carbide solution treated and strain hardened to reach considerably higher strength: minimum tensile of 125 ksi (860 MPa), yield of 100 ksi (690 MPa) and maximum hardness of 321 HBW or 35 HRC. These fittings are widely applied in the high strength piping bolting applications.

ASTM A193 B8 Stud Bolts, ASME SA193 Grade B8 Hex Bolts, B8 Screws Supplier & Exporter

Jade Special Metals is a well-known stockist and dealer of quality fasteners and especially ASTM A193 B8 Stud Bolts. Our products are manufactured with superior characteristics, such as rigid design, longer life cycle, low maintenance, and fine finish, which guarantee the dimensional accuracy and convenience of use. We also offer customization of our ASME SA 193 B8 bolts to offer different lengths and tolerances to satisfy the client’s needs.

Table of Contents

- Types of A193 B8 Fasteners

- Specifications of ASTM A193 Grade B8 Bolts

- Chemical Composition of ASTM A193 Grade B8 Bolts

- ASTM A193 Grade B8 Mechanical Properties Inch Product

- ASTM A193 Grade B8 Mechanical Properties Metric Product

- Equivalent Grade of ASTM A193 Grade B8 Bolt

- Size Chart of ASTM A193 B8 Bolt

- Dimensions chart of ASTM A193 B8 Heavy Hex Bolt

- ASTM A193 B8 Bolts Inventory

- Applications of ASTM A193 B8 Bolts

Types of A193 B8 Fasteners

A193 B8 Bolts

A193 B8 Double-ended studs

A193 B8 Nuts

A193 B8 Screws

A193 B8 Stud bolts

A193 B8 Hex bolts

A193 B8 Anchor bolts

A193 B8 Threaded rods

A193 B8 Eye bolts

A193 B8 Heavy hex bolts

A193 B8 U-bolts

A193 B8 Washers

Specifications of ASTM A193 Grade B8 Bolts

| Standards | Designation |

|---|---|

| Dimensions | ASME B18.2.1, B18.3 |

| Melt Origin | Soutd America/East Europe/JapanKorea/ |

| Product Origin | Made in India |

| Threads Configuration | ASME B1.1 2A/3A Inch Unified Threads and B1.13M 6h Metric Coarse Threads |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Additional Certifications | PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified |

| Mandatory Requirements | Free from Mercury & Radioactive Contamination |

| Additional Requirements | NACE MR0103 / MR0175 / ISO 15156 Compliance |

Chemical Composition of ASTM A193 Grade B8 Bolts

| Property class | C. | Mn. | Si. | P. | S. | Cr. | Ni. | Mo. | V. | Ti. |

|---|---|---|---|---|---|---|---|---|---|---|

| B8 | 0.08 max. | 2.00 max. | 1.00 max. | 0.045 max. | 0.030 max. | 18.00-20.00 | 8.00-10.50 | — | — | — |

ASTM A193 Grade B8 Mechanical Properties Inch Product

| Class, Diameter In | Heat Treatment B | Tensile Strength, min, ksi | Yield Strength, min, 0.2 % offset, ksi | Elongation in 4 D, min % | Reduction of Area, min % | Hardness, max |

|---|---|---|---|---|---|---|

| B8 | carbide solution treated | 75 | 30 | 30 | 50 | 223 HB C or 96 HRB |

ASTM A193 Grade B8 Mechanical Properties Metric Product

| Class, Diameter mm | Heat TreatmentB | Tensile Strength, min, ksi | Yield Strength, min, 0.2 % offset, ksi | Elongation in 4 D, min % | Reduction of Area, min % | Hardness, max |

|---|---|---|---|---|---|---|

| B8 | carbide solution treated | 515 | 205 | 30 | 50 | 223 HBC or 96 HRB |

Equivalent Grade of ASTM A193 Grade B8 Bolt

| Grade | 304 | 304 L | 310 | 310 S | 316 | 316 L | 316S31 | 410 | 431 | |

|---|---|---|---|---|---|---|---|---|---|---|

| ASTM | America | ASTM A 193 Gr B8 | ASTM A 320 Ge B8 | ASTM A 479 | ASTM A 193 Gr B8M | ASTM A 320 Ge B8M | ASTM A 193 Gr B8M | |||

| EN | European | 1.4301 | 1.4306 | 1.4841 | 1.4845 | 1.4401 | 1.4404 | 1.4401 | 1.4006 | 1.4057 |

| BS | British | BS 970 | BS 970 | BS 970 | BS 970 | BS 970 | BS 970 | BS 970 | BS 970 | BS 970 |

| UNS | North America | S30400 | S30403 | S31000 | S31008 | S31600 | S31603 | S31600 | S41000 | S43100 |

| DIN | German | X 5CrNi1810 | X 2CrNi1911 | X 12 CrNi 25 21 | X 12 CrNi 25 21 | X 5 CrNiMo 17 13 2 | X 2 CrNiMo 17 13 2 | X 5 CrNiMo 17 12 2 | X 10Cr13 | X 20CrNi172 |

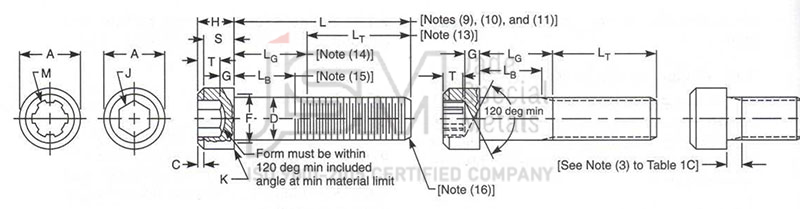

Size Chart of ASTM A193 B8 Bolt

| Nominal Basic | Size or Screw | Body | D Diameter | Head | A Diameter | Head | H Height | $ Head Side Height | J Hex Socket Size | T Key Engagmt | G Wall Thkns | K Chamfer or Radius |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Diameter | Max | Min | Max | Min | Max | Min | Max | Nominal | Min | Min | Max | |

| 0 | 0.0600 | 0.0600 | 0.0568 | 0.096 | 0.091 | 0.060 | 0.057 | 0.054 | 0.050 | 0.025 | 0.020 | 0.003 |

| 1 | 0.0730 | 0.0730 | 0.0695 | 0.118 | 0.112 | 0.073 | 0.070 | 0.066 | 1/16 0.062 | 0.031 | 0.025 | 0.003 |

| 2 | 0.0860 | 0.0860 | 0.0822 | 0.140 | 0.134 | 0.086 | 0.083 | 0.077 | 5/64 0.078 | 0.038 | 0.029 | 0.003 |

| 3 | 0.0990 | 0.0990 | 0.0949 | 0.161 | 0.154 | 0.099 | 0.095 | 0.089 | 5/64 0.078 | 0.044 | 0.034 | 0.003 |

| 4 | 0.1120 | 0.1120 | 0.1075 | 0.183 | 0.176 | 0.112 | 0.108 | 0.101 | 3/32 0.094 | 0.051 | 0.038 | 0.005 |

| 5 | 0.1250 | 0.1250 | 0.1202 | 0.205 | 0.198 | 0.125 | 0.121 | 0.112 | 3/32 0.094 | 0.057 | 0.043 | 0.005 |

| 6 | 0.1380 | 0.1380 | 0.1329 | 0.226 | 0.218 | 0.138 | 0.134 | 0.124 | 7/64 0.109 | 0.064 | 0.047 | 0.005 |

| 8 | 0.1640 | 0.1640 | 0.1585 | 0.270 | 0.262 | 0.164 | 0.159 | 0.148 | 9/64 0.141 | 0.077 | 0.056 | 0.005 |

| 10 | 0.1900 | 0.1900 | 0.1840 | 0.312 | 0.303 | 0.190 | 0.185 | 0.171 | 5/32 0.156 | 0.090 | 0.065 | 0.005 |

| 1/4 | 0.2500 | 0.2500 | 0.2435 | 0.375 | 0.365 | 0.250 | 0.244 | 0.225 | 3/16 0.188 | 0.120 | 0.095 | 0.008 |

| 5/16 | 0.3125 | 0.3125 | 0.3053 | 0.469 | 0.457 | 0.312 | 0.306 | 0.281 | 1/4 0.250 | 0.151 | 0.119 | 0.008 |

| 3/8 | 0.3750 | 0.3750 | 0.3678 | 0.562 | 0.550 | 0.375 | 0.368 | 0.337 | 5/16 0.312 | 0.182 | 0.143 | 0.008 |

| 7/16 | 0.4375 | 0.4375 | 0.4294 | 0.656 | 0.642 | 0.438 | 0.430 | 0.394 | 3/8 0.375 | 0.213 | 0.166 | 0.010 |

| 1/2 | 0.5000 | 0.5000 | 0.4919 | 0.750 | 0.735 | 0.500 | 0.492 | 0.450 | 3/8 0.375 | 0.245 | 0.190 | 0.010 |

| 5/8 | 0.6250 | 0.6250 | 0.6163 | 0.938 | 0.921 | 0.625 | 0.616 | 0.562 | 1/2 0.500 | 0.307 | 0.238 | 0.010 |

| 3/4 | 0.7500 | 0.7500 | 0.7406 | 1.125 | 1.107 | 0.750 | 0.740 | 0.675 | 5/8 0.625 | 0.370 | 0.285 | 0.010 |

| 7/8 | 0.8750 | 0.8750 | 0.8647 | 1.312 | 1.293 | 0.875 | 0.864 | 0.787 | 3/4 0.750 | 0.432 | 0.333 | 0.015 |

| 1 | 1.0000 | 1.0000 | 0.9886 | 1.500 | 1.479 | 1.000 | 0.988 | 0.900 | 3/4 0.750 | 0.495 | 0.380 | 0.015 |

| See Notes | 1 | 2,15 | 3 | 4 | 21 | 6 |

“Contact Jade Special Metals today with your requirement for ASTM A193 B8 Bolts. We assure you of the best quote.

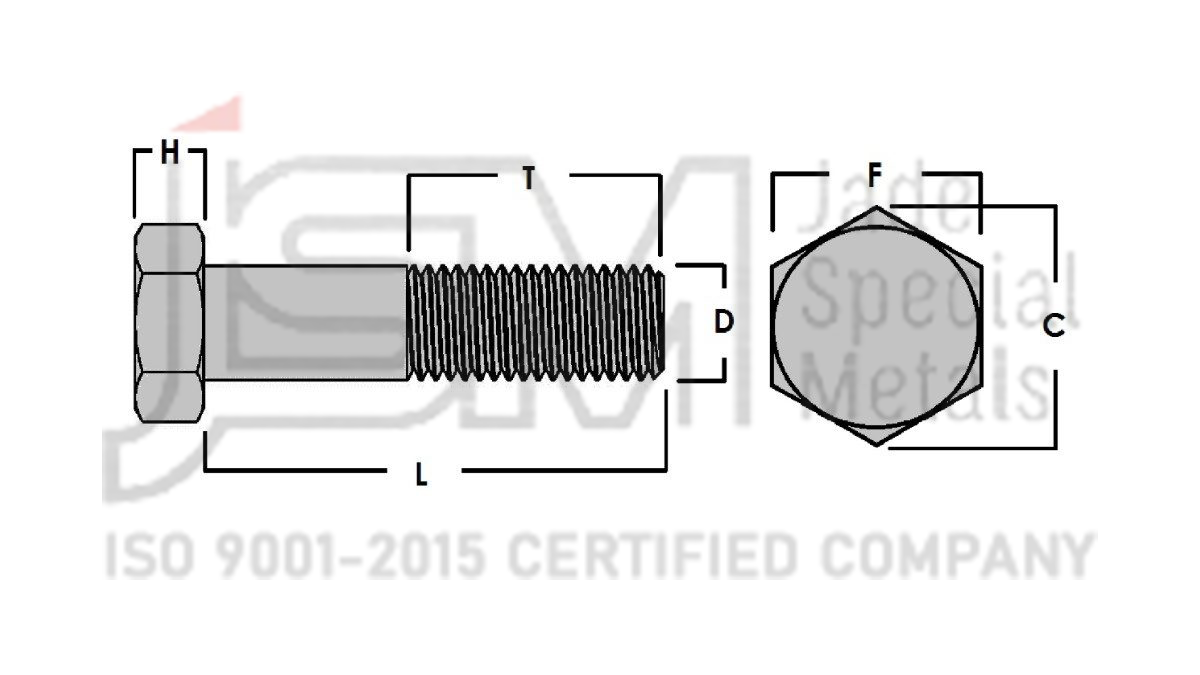

Dimensions chart of ASTM A193 B8 Heavy Hex Bolt

| Diameter (D) | Body Diameter (D) | Across the Flats (F) | Across the Corners © | Head Height (H) | Thread Lengths (T) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| MAX | MIN | MAX | MIN | MAX | MIN | MAX | MIN | < 6” | > 6” | |

| 1/2 | 0.515 | 0.482 | 0.875 | 0.85 | 1.01 | 0.969 | 0.364 | 0.302 | 1.25 | 1.5 |

| 5/8 | 0.642 | 0.605 | 1.062 | 1.031 | 1.227 | 1.175 | 0.444 | 0.378 | 1.5 | 1.75 |

| 3/4 | 0.768 | 0.729 | 1.25 | 1.212 | 1.443 | 1.383 | 0.524 | 0.455 | 1.75 | 2 |

| 7/8 | 0.895 | 0.852 | 1.438 | 1.394 | 1.66 | 1.589 | 0.604 | 0.531 | 2 | 2.25 |

| 1 | 1.022 | 0.976 | 1.625 | 1.575 | 1.876 | 1.796 | 0.7 | 0.591 | 2.25 | 2.5 |

| 1 1/8 | 1.149 | 1.098 | 1.812 | 1.756 | 2.093 | 2.002 | 0.78 | 0.658 | 2.5 | 2.75 |

| 1 1/4 | 1.277 | 1.223 | 2 | 1.938 | 2.309 | 2.209 | 0.876 | 0.749 | 2.75 | 3 |

| 1 3/8 | 1.404 | 1.345 | 2.188 | 2.119 | 2.526 | 2.416 | 0.94 | 0.81 | 3 | 3.25 |

| 1 1/2 | 1.531 | 1.47 | 2.375 | 2.3 | 2.742 | 2.622 | 1.036 | 0.902 | 3.25 | 3.5 |

| 1 3/4 | 1.785 | 1.716 | 2.75 | 2.662 | 3.175 | 3.035 | 1.196 | 1.054 | 3.75 | 4 |

| 2 | 2.039 | 1.964 | 3.125 | 3.025 | 3.608 | 3.449 | 1.388 | 1.175 | 4.25 | 4.5 |

| 2 1/4 | 2.305 | 2.214 | 3.5 | 3.388 | 4.041 | 3.862 | 1.548 | 1.327 | 4.75 | 5 |

| 2 1/2 | 2.559 | 2.461 | 3.875 | 3.75 | 4.474 | 4.275 | 1.708 | 1.479 | 5.25 | 5.5 |

| 2 3/4 | 2.827 | 2.711 | 4.25 | 4.112 | 4.907 | 4.688 | 1.869 | 1.632 | 5.75 | 6 |

| 3 | 3.081 | 2.961 | 4.625 | 4.475 | 5.34 | 5.102 | 2.06 | 1.815 | 6.25 | 6.5 |

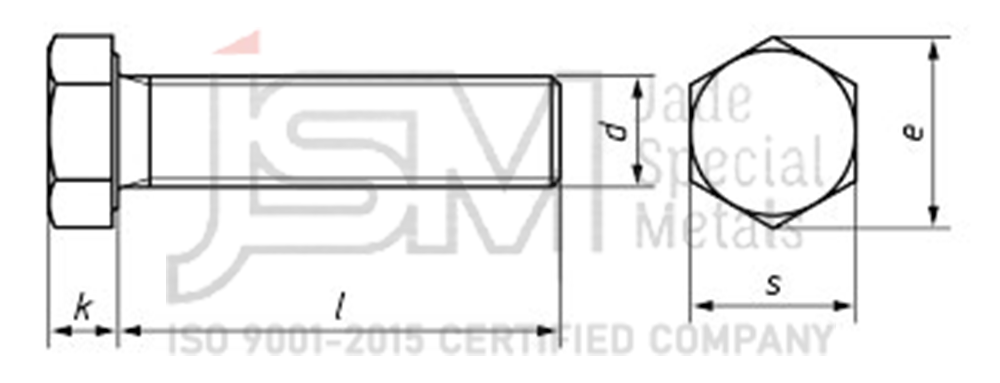

Dimensions of ASTM A193 Grade B8 Stainless Steel Fasteners

| NOMINAL SIZE (D) | BODY DIAMETER | HEAD THICKNEASTM A193 | ACROASTM A193 THE FLATS | ACROASTM A193 CORNERS | ||||

|---|---|---|---|---|---|---|---|---|

| D (MAX) | D (MIN) | H (MAX) | H (MIN) | F (MAX) | F (MIN) | C (MAX) | C (MIN) | |

| m14 | 14.00 | 13.73 | 9.09 | 8.51 | 22.00 | 20.67 | 24.25 | 23.35 |

| m10 | 10.00 | 9.78 | 6.63 | 6.17 | 17.00 | 15.73 | 18.48 | 17.77 |

| m12 | 12.00 | 11.73 | 7.76 | 4.24 | 19.00 | 17.73 | 20.78 | 20.03 |

| m16 | 16.00 | 15.73 | 10.32 | 9.68 | 24.00 | 23.67 | 27.71 | 26.75 |

| m24 | 24.00 | 23.67 | 15.44 | 14.56 | 36.00 | 35.00 | 41.57 | 39.55 |

| m30 | 30.00 | 29.67 | 19.48 | 17.92 | 46.00 | 45.00 | 53.12 | 50.85 |

| m36 | 36.00 | 35.61 | 23.38 | 21.63 | 55.00 | 53.80 | 63.51 | 60.79 |

| m20 | 20.00 | 19.67 | 12.88 | 12.12 | 30.00 | 29.16 | 34.64 | 32.95 |

| m42 | 42.00 | 41.38 | 26.97 | 25.03 | 65.00 | 62.90 | 75.06 | 71.71 |

| m48 | 48.00 | 47.38 | 31.07 | 28.93 | 75.00 | 72.60 | 86.60 | 82.76 |

| m80 | 80.00 | 79.26 | 51.58 | 48.42 | 115.00 | 111.00 | 132.72 | 126.54 |

| m64 | 64.00 | 63.26 | 41.32 | 38.68 | 95.00 | 91.80 | 109.70 | 104.65 |

| m72 | 72.00 | 71.26 | 46.45 | 43.55 | 105.00 | 101.40 | 121.24 | 115.60 |

| m90 | 90.00 | 89.13 | 57.74 | 54.26 | 130.00 | 125.50 | 150.11 | 143.07 |

| m56 | 56.00 | 55.26 | 36.2 | 33.80 | 85.00 | 82.20 | 98.15 | 93.71 |

| m100 | 90.00 | 99.13 | 63.9 | 60.10 | 145.00 | 140.00 | 167.43 | 159.60 |

Torque Chart For Grade B8 Stud Bolt

| TORQUE NM – ASTM A193 GRADE B8 Class 2 STUD BOLTS | |||

|---|---|---|---|

| BOLTS DIA |

TORQUE NM | ||

| 70% Torque |

30% Initial Torque |

100% Final Torque |

|

| 1/2 | 49 | 22 | 71 |

| 9/16 | 72 | 31 | 102 |

| 5/8 | 99 | 42 | 141 |

| 3/4 | 175 | 75 | 249 |

| 7/8 | 225 | 96 | 321 |

| 1 | 338 | 145 | 483 |

| 1⅛ | 403 | 172 | 575 |

| 1¼ | 565 | 243 | 808 |

| 1⅜ | 590 | 252 | 843 |

| 1½ | 778 | 334 | 1113 |

| 19/16 | 531 | 228 | 759 |

| 1⅝ | 603 | 259 | 862 |

| 1¾ | 761 | 325 | 1086 |

| 1⅞ | 944 | 404 | 1348 |

| 2 | 1157 | 496 | 1653 |

| 2¼ | 1673 | 717 | 2389 |

| 2½ | 2317 | 994 | 3311 |

| 2¾ | 3118 | 1337 | 4454 |

| 3 | 4078 | 1748 | 5826 |

Applications of ASTM A193 B8 Bolts

- Petrochemicals

- Heat Exchangers

- Power Generation

- Pharmaceutical Equipment

- Gas Processing

- Aircraft Exhaust Manifolds

- Spiral Welded tube for burner pipes and flues

- Pharmaceuticals

- Specialty Chemicals

- Off-Shore Oil Drilling Companies

- Sea Water Equipment

Related Products

ASTM A193 B8 Bolts Price

| Product | Thread Size | USD | INR | AED |

|---|---|---|---|---|

| ASTM A193 B8 Bolts | 1/2″ | $0.20 | ₹15 | د.إ0.734 |

| SA 193 Gr B8 Heavy Hex Bolt | M4 | $0.50 | ₹37.5 | د.إ1.835 |

| A193 B8 Hex Bolts | 5/8″ | $0.20 | ₹15 | د.إ0.734 |

| ASTM A193 Grade B8 Alloy Steel U Bolts | M20 | $0.40 | ₹30 | د.إ1.468 |

| ASME SA193 Gr B8 Hex Head Bolt | M6-M20 | $0.02 | ₹1.5 | د.إ0.0734 |

| A193 Grade B8 Square Bolts | M8 | $0.02 | ₹1.5 | د.إ0.0734 |

| ASTM A 193 GR B8 Eye Bolts | M2-M6 | $0.08 | ₹6 | د.إ0.2936 |

| B8 Steel Flange Bolts | M3-M30 | $0.13 | ₹9.75 | د.إ0.4771 |

FAQ’s About ASTM A193 B8 Bolts

What is A193 B8 bolt material?

ASTM A193 B8 is a standard specification for fasteners manufactured from Grade 304 (UNS S30400) austenitic stainless steel. These bolts are specifically designed for high-temperature and high-pressure service where corrosion resistance is a primary requirement.

What is the difference between A193 B8 and B7?

ASTM A193 Grade B7 and Grade B8 fasteners are used for different jobs in industrial settings. B7 fasteners are prized for their excellent strength and high-temperature resistance. In contrast, B8 fasteners are chosen for their superior corrosion resistance, though they offer only moderate strength compared to B7.

What is the hardness of A193 B8?

The maximum hardness depends on the class. A193 B8 Class 1 has a maximum hardness of 223 HBW (or 96 HRB). A193 B8 Class 2, which is strain-hardened for higher strength, has a significantly higher maximum hardness of 321 HBW (or 35 HRC).

What is the difference between ASTM A193 B8 Class 2 and Class 1?

The difference lies in the manufacturing process and resulting strength.

- Class 1: Is carbide solution treated (annealed), which provides excellent corrosion resistance but lower strength (75 ksi minimum tensile).

- Class 2: Is solution treated and then strain-hardened (cold worked). This process significantly increases its strength (125 ksi minimum tensile for sizes up to ¾”) while maintaining good corrosion resistance.

What is A193 B8 equivalent to?

A193 B8 is not equivalent to another fastener specification but is defined by the material it’s made from. It is manufactured from AISI 304 stainless steel (UNS S30400), often referred to as 18-8 stainless steel due to its typical 18% chromium and 8% nickel content.