The ASTM A193 Grade B8M specification is the controlling ASTM standard that gives the specifications of high tensile bolting material manufactured using 316/316L stainless steel. This standard spells out the required chemical composition, mechanical properties, hardness, preferential heat treatment, product marking, and certification of fasteners that are to be used as service in high temperature, high-pressure, or other special applications. These bolts are applicable in the critical practice in pressure vessels, valves, flanges and fittings.

ASTM A193 Grade B8M fasteners have been separated into two unique property classes depending on the tensile strength they need. Class 1 material is carbide solution treated 316 stainless steel with tensile strength at least 75 ksi (515 Mpa), a yield strength at least 30 ksi (205 Mpa), and a hardness of up to 223 HBW. Class 2 metal is strain hardened to much greater levels of higher properties with required minimum tensile strength of 125 ksi (860 MPa), 100 ksi (690 MPa) of yield and 321 HBW (35 HRC) of maximum hardness.

ASME SA193 B8M Stud Bolt Manufacturer and Supplier in India

Jade Special Metals is an established producer of ASTM A193 B8M Stainless Steel Fasteners that are also distributed using the ASME SA 193 B8M designation. We have the following fasteners namely Hex Bolts and Stud Bolts and their features are good body, rough construction, easy fitting, good finish, and accurate design.

Such fasteners have received much applause in the industrial application because of its superior features, especially high resistance to corrosion, a corrosion-free finish, and long service life. Jade Special Metals makes sure that clients are supplied with a rich range of products of the highest quality, which are produced using high-quality materials and strictly tested in terms of quality.

Table of Contents

- Types of A193 B8M Fasteners

- ASTM A193 B8M Bolts Specifications

- ASTM A193 B8M Bolts Chemical Composition

- Mechanical Properties of ASTM A193 B8M Bolts

- ASTM A193 B8M Bolts Heat Treatment

- ASTM A193 B8M Class 1 Bolt Dimension Chart

- Dimension Chart of SA193 B8M Hex Bolts

- ASTM A193 B8M Bolts Inventory

- Applications of ASTM A193 B8M Bolts

Types of A193 B8M Fasteners

A193 B8M Socket Heads

A193 B8M Double End Studs

A193 B8M CSK Screws

A193 B8M Set Screws

A193 B8M Stud Bolts

A193 B8M Hex bolts

A193 B8M Anchor bolts

A193 B8M Threaded Rods

A193 B8M Hex Cap Screws

A193 B8M Heavy hex bolts

A193 B8M U-bolts

A193 B8M Eye bolts

ASTM A193 B8M Bolts Specification

| Standards | Designation |

|---|---|

| Dimensions | ASME B18.2.1, B18.3 |

| Melt Origin | Soutd America/East Europe/JapanKorea/ |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Threads Configuration | ASME B1.1 2A/3A Inch Unified Threads and B1.13M 6h Metric Coarse Threads |

| Additional Certifications | PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified |

| Mandatory Requirements | Free from Mercury & Radioactive Contamination |

| Product Origin | Made in India |

| Additional Requirements | NACE MR0103 / MR0175 / ISO 15156 Compliance |

ASTM A193 B8M Bolts Chemical Composition

| Element | Carbon | Manganese | Phosphorus, max | Sulfur, max | Silicon | Chromium | Nickel | Molybdenum |

|---|---|---|---|---|---|---|---|---|

| B8M (AISI 316) | 0.08% max | 2.00% max | 0.045% | 0.030% | 1.00% max | 16.0 – 18.0% | 10.0 – 14.0% | 2.00 – 3.00% |

Mechanical Properties of ASTM A193 B8M Bolts

| Grade | Size | Tensile ksi, min | Yield, ksi, min | Elong, %, min | RA % min | Hardness max |

|---|---|---|---|---|---|---|

| B8M Class 1 | All | 515 | 205 | 30 | 50 | 223 HBW or 96 HRB |

| B8M Class 2 | 760 | 665 | 15 | 45 | 321 HBW or 35 HRC | |

| Over M20 to M24 incl | 690 | 550 | 20 | 45 | 321 HBW or 35 HRC | |

| Over M24 to M30 incl | 655 | 450 | 25 | 45 | 321 HBW or 35 HRC | |

| Over M30 to M36 incl | 620 | 345 | 30 | 45 | 321 HBW or 35 HRC |

ASTM A193 B8M Bolts Heat Treatment

| Class | Heat Treatment Procedure |

|---|---|

| Class 1 | Carbide Solution Treatment |

| Class 2 | Carbide Solution Treatment & Strain Hardened |

ASTM A193 B8M Class 1 Bolt Dimension Chart

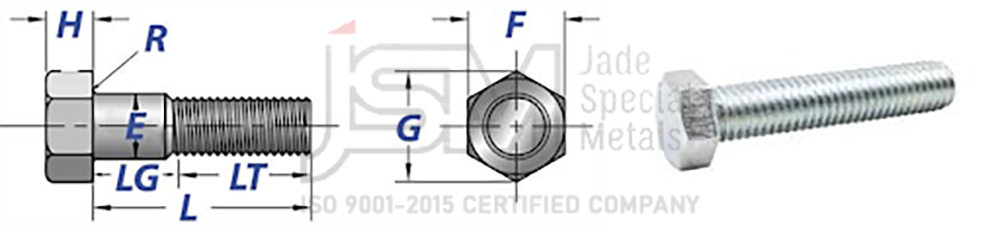

| Diameter (D) | Body Diameter (D) | Across the Flats (F) | Across the Corners © | Head Height (H) | Thread Lengths (T) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| MAX | MIN | MAX | MIN | MAX | MIN | MAX | MIN | < 6” | > 6” | |

| 1/2 | 0.515 | 0.482 | 0.875 | 0.85 | 1.01 | 0.969 | 0.364 | 0.302 | 1.25 | 1.5 |

| 3/4 | 0.768 | 0.729 | 1.25 | 1.212 | 1.443 | 1.383 | 0.524 | 0.455 | 1.75 | 2 |

| 7/8 | 0.895 | 0.852 | 1.438 | 1.394 | 1.66 | 1.589 | 0.604 | 0.531 | 2 | 2.25 |

| 5/8 | 0.642 | 0.605 | 1.062 | 1.031 | 1.227 | 1.175 | 0.444 | 0.378 | 1.5 | 1.75 |

| 1 | 1.022 | 0.976 | 1.625 | 1.575 | 1.876 | 1.796 | 0.7 | 0.591 | 2.25 | 2.5 |

| 1 1/8 | 1.149 | 1.098 | 1.812 | 1.756 | 2.093 | 2.002 | 0.78 | 0.658 | 2.5 | 2.75 |

| 2 1/4 | 2.305 | 2.214 | 3.5 | 3.388 | 4.041 | 3.862 | 1.548 | 1.327 | 4.75 | 5 |

| 1 1/4 | 1.277 | 1.223 | 2 | 1.938 | 2.309 | 2.209 | 0.876 | 0.749 | 2.75 | 3 |

| 1 3/8 | 1.404 | 1.345 | 2.188 | 2.119 | 2.526 | 2.416 | 0.94 | 0.81 | 3 | 3.25 |

| 1 1/2 | 1.531 | 1.47 | 2.375 | 2.3 | 2.742 | 2.622 | 1.036 | 0.902 | 3.25 | 3.5 |

| 1 3/4 | 1.785 | 1.716 | 2.75 | 2.662 | 3.175 | 3.035 | 1.196 | 1.054 | 3.75 | 4 |

| 2 | 2.039 | 1.964 | 3.125 | 3.025 | 3.608 | 3.449 | 1.388 | 1.175 | 4.25 | 4.5 |

| 2 1/2 | 2.559 | 2.461 | 3.875 | 3.75 | 4.474 | 4.275 | 1.708 | 1.479 | 5.25 | 5.5 |

| 2 3/4 | 2.827 | 2.711 | 4.25 | 4.112 | 4.907 | 4.688 | 1.869 | 1.632 | 5.75 | 6 |

| 3 | 3.081 | 2.961 | 4.625 | 4.475 | 5.34 | 5.102 | 2.06 | 1.815 | 6.25 | 6. |

“Contact Jade Special Metals today with your requirement for ASTM A193 B8M Bolts. We assure you of the best quote.

Dimension Chart of SA193 B8M Hex Bolts

| NOMINAL SIZE (D) | BODY DIAMETER | HEAD THICKNEASTM A193 | ACROASTM A193 THE FLATS | ACROASTM A193 CORNERS | ||||

|---|---|---|---|---|---|---|---|---|

| D (MAX) | D (MIN) | H (MAX) | H (MIN) | F (MAX) | F (MIN) | C (MAX) | C (MIN) | |

| m10 | 10.00 | 9.78 | 6.63 | 6.17 | 17.00 | 15.73 | 18.48 | 17.77 |

| m12 | 12.00 | 11.73 | 7.76 | 4.24 | 19.00 | 17.73 | 20.78 | 20.03 |

| m14 | 14.00 | 13.73 | 9.09 | 8.51 | 22.00 | 20.67 | 24.25 | 23.35 |

| m16 | 16.00 | 15.73 | 10.32 | 9.68 | 24.00 | 23.67 | 27.71 | 26.75 |

| m20 | 20.00 | 19.67 | 12.88 | 12.12 | 30.00 | 29.16 | 34.64 | 32.95 |

| m24 | 24.00 | 23.67 | 15.44 | 14.56 | 36.00 | 35.00 | 41.57 | 39.55 |

| m30 | 30.00 | 29.67 | 19.48 | 17.92 | 46.00 | 45.00 | 53.12 | 50.85 |

| m36 | 36.00 | 35.61 | 23.38 | 21.63 | 55.00 | 53.80 | 63.51 | 60.79 |

| m42 | 42.00 | 41.38 | 26.97 | 25.03 | 65.00 | 62.90 | 75.06 | 71.71 |

| m48 | 48.00 | 47.38 | 31.07 | 28.93 | 75.00 | 72.60 | 86.60 | 82.76 |

| m56 | 56.00 | 55.26 | 36.2 | 33.80 | 85.00 | 82.20 | 98.15 | 93.71 |

| m64 | 64.00 | 63.26 | 41.32 | 38.68 | 95.00 | 91.80 | 109.70 | 104.65 |

| m72 | 72.00 | 71.26 | 46.45 | 43.55 | 105.00 | 101.40 | 121.24 | 115.60 |

| m80 | 80.00 | 79.26 | 51.58 | 48.42 | 115.00 | 111.00 | 132.72 | 126.54 |

| m90 | 90.00 | 89.13 | 57.74 | 54.26 | 130.00 | 125.50 | 150.11 | 143.07 |

| m100 | 90.00 | 99.13 | 63.9 | 60.10 | 145.00 | 140.00 | 167.43 | 159.60 |

A193 B8M Class 1 Hex Bolt Torque Chart

| NOMINAL SIZE (D) | BODY DIAMETER | HEAD THICKNEASTM A193 | ACROASTM A193 THE FLATS | ACROASTM A193 CORNERS | ||||

|---|---|---|---|---|---|---|---|---|

| D (MAX) | D (MIN) | H (MAX) | H (MIN) | F (MAX) | F (MIN) | C (MAX) | C (MIN) | |

| m12 | 12.00 | 11.73 | 7.76 | 4.24 | 19.00 | 17.73 | 20.78 | 20.03 |

| m48 | 48.00 | 47.38 | 31.07 | 28.93 | 75.00 | 72.60 | 86.60 | 82.76 |

| m14 | 14.00 | 13.73 | 9.09 | 8.51 | 22.00 | 20.67 | 24.25 | 23.35 |

| m10 | 10.00 | 9.78 | 6.63 | 6.17 | 17.00 | 15.73 | 18.48 | 17.77 |

| m16 | 16.00 | 15.73 | 10.32 | 9.68 | 24.00 | 23.67 | 27.71 | 26.75 |

| m20 | 20.00 | 19.67 | 12.88 | 12.12 | 30.00 | 29.16 | 34.64 | 32.95 |

| m24 | 24.00 | 23.67 | 15.44 | 14.56 | 36.00 | 35.00 | 41.57 | 39.55 |

| m30 | 30.00 | 29.67 | 19.48 | 17.92 | 46.00 | 45.00 | 53.12 | 50.85 |

| m36 | 36.00 | 35.61 | 23.38 | 21.63 | 55.00 | 53.80 | 63.51 | 60.79 |

| m42 | 42.00 | 41.38 | 26.97 | 25.03 | 65.00 | 62.90 | 75.06 | 71.71 |

| m56 | 56.00 | 55.26 | 36.2 | 33.80 | 85.00 | 82.20 | 98.15 | 93.71 |

| m64 | 64.00 | 63.26 | 41.32 | 38.68 | 95.00 | 91.80 | 109.70 | 104.65 |

| m80 | 80.00 | 79.26 | 51.58 | 48.42 | 115.00 | 111.00 | 132.72 | 126.54 |

| m90 | 90.00 | 89.13 | 57.74 | 54.26 | 130.00 | 125.50 | 150.11 | 143.07 |

| m72 | 72.00 | 71.26 | 46.45 | 43.55 | 105.00 | 101.40 | 121.24 | 115.60 |

| m100 | 90.00 | 99.13 | 63.9 | 60.10 | 145.00 | 140.00 | 167.43 | 159.60 |

ASTM A193 B8M Bolts Inventory

ASTM A193 B8M Stud Bolts

ASTM A193 B8M Hex Bolts

Applications of ASTM A193 B8M Bolts

- Oil & Gas Industry

- Petrochemical & Chemical Processing

- Power Generation

- Marine & Shipbuilding

- Pulp & Paper Industry

- Food & Beverage Processing

- General Industrial Assemblies