The Grade L7 specification is a part of ASTM A320, which is a wider range of the ASTM A320 standard, which includes mechanical properties of fasteners made of carbon and alloy steel, and with low-temperature use. In particular, Grade L7 is related to bolting materials rolled, forged or strain-hardened bars, bolts, screws, studs and stud bolts, which are often utilized in the work with pressure vessels, valves, flanges and fittings. The other popular grades under this standard are L7M and L43. Just like in the ASTM A193 specification of high temperature service, the larger than 1 inch diameter fasteners normally employ a 8UN thread series, although this can be changed on an individual request basis by the user.

The ASTM specification of A320 Grade L7, as developed under the ASTM standard, refers to the bolts, studs, nuts, and other fasteners that are specifically designed to work in high temperatures, even though the general ASTM A320 standard is known to be used in low-temperature conditions. The material is categorized into four classes of property (A, B, C, and D) which have different tensile and stress rupture characteristics. ASTM standard Grade L7 bolts are used in bolting construction of boilers, pressure vessels, and pipeline connections as well as valves with high temperatures. The A320 Grade L7 material is a chemical equivalent of the ASTM B638 Grade 660 stainless steel alloy (also called Alloy A286 or UNS S66286) which is heat-treated to satisfy the mechanical properties specified in the ASTM A453 specification.

ASTM A320 Grade L7 Specification

The ASTM specification of A320 Grade L7, as developed under the ASTM standard, refers to the bolts, studs, nuts, and other fasteners that are specifically designed to work in high temperatures, even though the general ASTM A320 standard is known to be used in low-temperature conditions. The material is categorized into four classes of property (A, B, C, and D) which have different tensile and stress rupture characteristics. ASTM standard Grade L7 bolts are used in bolting construction of boilers, pressure vessels, and pipeline connections as well as valves with high temperatures. The A320 Grade L7 material is a chemical equivalent of the ASTM B638 Grade 660 stainless steel alloy (also called Alloy A286 or UNS S66286) which is heat-treated to satisfy the mechanical properties specified in the ASTM A453 specification.

ASTM A320 Grade L7 Stud Bolts Manufacturer and Supplier

Jade Special Metals produces and distributes a full stock of Grade L7 fasteners of ASTM A320, which comprise bolts, screws, studs, stud bolts, threaded rods, and round bars. Our products come in all sizes and in all thread types, and we have the most popular types of ASTM fasteners, which include hex bolts, heavy hex bolts, hex cap screws, socket head cap screws, set screws, full threaded stud bolts, double end studs, eye bolts and anchor bolts.

ASTM A320 Grade L7

| L7 |  |

Hex bolts, screws, stud bolts, double ended studs, Stud for foundation, wind energy bolts, Fasteners for wind turbines |

Table of Contents

- Types of ASTM A320 L7 Fasteners

- ASTM A320 L7 Bolt Specification

- ASTM A320 L7 Bolt Equivalent Grades

- ASTM A320 Grade L7 Chemical Composition

- ASTM A320 Grade L7 Mechanical Properties

- Dimensions Of ASTM A320 L7 Bolt

- A320 Grade L7 Heavy Hex Bolt Size Chart

- ASTM A320 Grade L7m Bolts Torque Chart

- A320 Grade L7 Hex Head Bolt Weight Chart

- ASTM A320 L7 Bolts Inventory

- Applications of ASTM A320 L7 Bolts

Types of ASTM A320 L7 Fasteners

ASTM A320 L7 Hex Cap Screws

ASTM A320 L7 Double End Studs

ASTM A320 L7 Heavy Hex Bolts

ASTM A320 L7 CSK Screws

ASTM A320 L7 Stud Bolts

ASTM A320 L7 Hex Bolts

ASTM A320 L7 Anchor Bolts

ASTM A320 L7 Threaded Rods

ASTM A320 L7 Eye Bolts

ASTM A320 L7 U-Bolts

ASTM A320 L7 Socket Head

ASTM A320 L7 Bolt Specification

| Standards | Designation |

|---|---|

| Dimensions | ASME B18.2.1, B18.3 |

| Melt Origin | Korea, South America, Japan, East Europe, |

| Mandatory Requirements | Free from Mercury & Radioactive Contamination |

| Additional Certifications | PED 97/ 23/ EC Certified, Merkblatt AD 2000 W2 Certified |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Additional Requirements | NACE MR0103 / MR0175 / ISO 15156 Compliance |

| Threads Configuration | ASME B1.1 2A/3A Inch Unified Threads and B1.13M 6h Metric Coarse Threads |

ASTM A320 L7 Bolt Equivalent Grades

| ASTM | AISI |

|---|---|

| ASTM A320 GRADE L7 | 4140 |

ASTM A320 Grade L7 Chemical Composition

| Property class | C. | Mn. | Si. | P. | S. | Cr. | Ni. | Mo. | V. | Ti. |

|---|---|---|---|---|---|---|---|---|---|---|

| L7 | 0.38—0.48 | 0.75—1.00 | 0.15—0.35 | 0.035 max. | 0.040 max. | 0.80—1.10 | – | 0.15-0.25 | – | – |

ASTM A320 Grade L7 Mechanical Properties

| Tensile Class | Tensile Strength, min | Yield strength, 0.2% offset, min | Elongation in 4D min, % | Reduction of Area, min, % | ||

|---|---|---|---|---|---|---|

| ksi | MPa | ksi | MPa | |||

| A, B and C | 130 | 895 | 85 | 585 | 15 | 18 |

| D | 130 | 895 | 105 | 725 | 15 | 18 |

“Contact Jade Special Metals today with your requirement for ASTM A320 L7 Bolts. We assure you of the best quote.

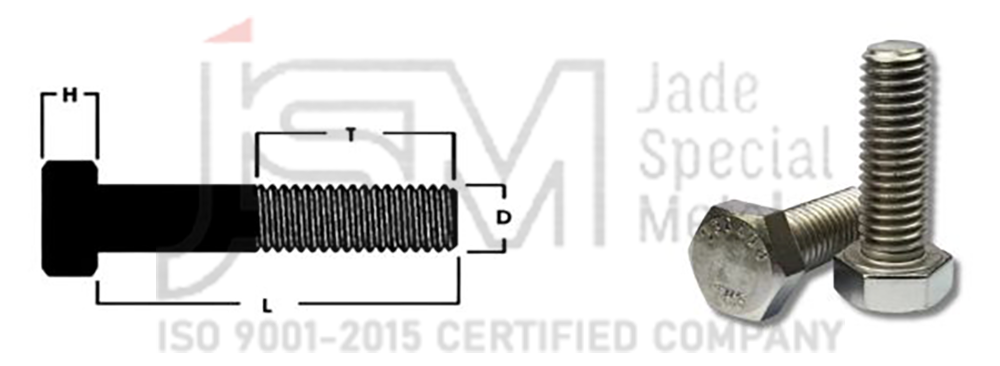

Dimensions Of ASTM A320 L7 Bolt

| Nominal Size or Basic Product Diameter |

Full-Size Body Diameter, E |

Width Across Flats, F |

Width Across Corners, G |

Head Height, H Basic | Radius of Fillet, R |

Nominal Thread Length for Bolt Lengths, LT |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| inch | mm | Max | Min | Basic inch |

Max | Min | Max | Min | Basic inch |

Max | Min | Max | Min | 6 in. and Shoter |

Over 6 in. |

| 1⁄4 | 0.25 | 0.26 | 0.237 | 7⁄16 | 0.438 | 0.425 | 0.505 | 0.484 | 11⁄64 | 0.188 | 0.15 | 0.03 | 0.01 | 0.75 | 1 |

| 5⁄16 | 0.3125 | 0.324 | 0.298 | 1⁄2 | 0.5 | 0.484 | 0.577 | 0.552 | 7⁄32 | 0.235 | 0.195 | 0.03 | 0.01 | 0.875 | 1.125 |

| 3⁄8 | 0.375 | 0.388 | 0.36 | 9⁄16 | 0.562 | 0.544 | 0.65 | 0.62 | 1⁄4 | 0.268 | 0.226 | 0.03 | 0.01 | 1 | 1.25 |

| 7⁄16 | 0.4375 | 0.452 | 0.421 | 5⁄8 | 0.625 | 0.603 | 0.722 | 0.687 | 19⁄64 | 0.316 | 0.272 | 0.03 | 0.01 | 1.125 | 1.375 |

| 1⁄2 | 0.5 | 0.515 | 0.482 | 3⁄4 | 0.75 | 0.725 | 0.866 | 0.826 | 11⁄32 | 0.364 | 0.302 | 0.03 | 0.01 | 1.25 | 1.5 |

| 5⁄8 | 0.625 | 0.642 | 0.605 | 15⁄16 | 0.938 | 0.906 | 1.083 | 1.033 | 27⁄64 | 0.444 | 0.378 | 0.06 | 0.02 | 1.5 | 1.75 |

| 3⁄4 | 0.75 | 0.768 | 0.729 | 11⁄8 | 1.125 | 1.088 | 1.299 | 1.24 | 1⁄2 | 0.524 | 0.455 | 0.06 | 0.02 | 1.75 | 2 |

| 7⁄8 | 0.875 | 0.895 | 0.852 | 1 5⁄16 | 1.312 | 1.269 | 1.516 | 1.447 | 37⁄64 | 0.604 | 0.531 | 0.06 | 0.02 | 2 | 2.25 |

| 1 | 1 | 1.022 | 0.976 | 1 1⁄2 | 1.5 | 1.45 | 1.732 | 1.653 | 43⁄64 | 0.7 | 0.591 | 0.09 | 0.03 | 2.25 | 2.5 |

| 1 1⁄8 | 1.125 | 1.149 | 1.098 | 1 11⁄16 | 1.688 | 1.631 | 1.949 | 1.859 | 3⁄4 | 0.78 | 0.658 | 0.09 | 0.03 | 2.5 | 2.75 |

| 1 1⁄4 | 1.25 | 1.277 | 1.223 | 1 7⁄8 | 1.875 | 1.812 | 2.165 | 2.066 | 27⁄32 | 0.876 | 0.749 | 0.09 | 0.03 | 2.75 | 3 |

| 1 3⁄8 | 1.375 | 1.404 | 1.345 | 2 1⁄16 | 2.062 | 1.994 | 2.382 | 2.273 | 29⁄32 | 0.94 | 0.81 | 0.09 | 0.03 | 3 | 3.25 |

| 1 1⁄2 | 1.5 | 1.531 | 1.47 | 2 1⁄4 | 2.25 | 2.175 | 2.598 | 2.48 | 1 | 1.036 | 0.902 | 0.09 | 0.03 | 3.25 | 3.5 |

| 1 5⁄8 | 1.625 | 1.658 | 1.591 | 2 7⁄16 | 2.438 | 2.356 | 2.815 | 2.616 | 1 3⁄32 | 1.116 | 0.978 | 0.09 | 0.03 | 3.5 | 3.75 |

| 1 3⁄4 | 1.75 | 1.785 | 1.716 | 2 5⁄8 | 2.625 | 2.538 | 3.031 | 2.893 | 1 5⁄32 | 1.196 | 1.054 | 0.12 | 0.04 | 3.75 | 4 |

| 1 7⁄8 | 1.875 | 1.912 | 1.839 | 2 13⁄16 | 2.812 | 2.719 | 3.248 | 3.099 | 1 1⁄4 | 1.276 | 1.13 | 0.12 | 0.04 | 4 | 4.25 |

| 2 | 2 | 2.039 | 1.964 | 3 | 3 | 2.9 | 3.464 | 3.306 | 1 11⁄32 | 1.388 | 1.175 | 0.12 | 0.04 | 4.25 | 4.5 |

| 2 1⁄4 | 2.25 | 2.305 | 2.214 | 3 3⁄8 | 3.375 | 3.262 | 3.897 | 3.719 | 1 1⁄2 | 1.548 | 1.327 | 0.19 | 0.06 | 4.75 | 5 |

| 2 1⁄2 | 2.5 | 2.559 | 2.461 | 3 3⁄4 | 3.75 | 3.625 | 4.33 | 4.133 | 1 21⁄32 | 1.708 | 1.479 | 0.19 | 0.06 | 5.25 | 5.5 |

| 2 3⁄4 | 2.75 | 2.827 | 2.711 | 4 1⁄8 | 4.125 | 3.988 | 4.763 | 4.546 | 1 13⁄16 | 1.869 | 1.632 | 0.19 | 0.06 | 5.75 | 6 |

| 3 | 3 | 3.081 | 2.961 | 4 1⁄2 | 4.5 | 4.35 | 5.196 | 4.959 | 2 | 2.06 | 1.815 | 0.19 | 0.06 | 6.25 | 6.5 |

| 3 1⁄4 | 3.25 | 3.335 | 3.21 | 4 7⁄8 | 4.875 | 4.712 | 5.629 | 5.372 | 2 3⁄16 | 2.251 | 1.936 | 0.19 | 0.06 | 6.75 | 7 |

| 3 1⁄2 | 3.5 | 3.589 | 3.461 | 5 1⁄4 | 5.25 | 5.075 | 6.062 | 5.786 | 2 5⁄16 | 2.38 | 2.057 | 0.19 | 0.06 | 7.25 | 7.5 |

| 3 3⁄4 | 3.75 | 3.858 | 3.726 | 5 5⁄8 | 5.625 | 5.437 | 6.495 | 6.198 | 2 1⁄2 | 2.572 | 2.241 | 0.19 | 0.06 | 7.75 | 8 |

| 4 | 4 | 4.111 | 3.975 | 6 | 6 | 5.8 | 6.928 | 6.612 | 2 11⁄16 | 2.764 | 2.424 | 0.19 | 0.06 | 8.25 | 8.5 |

A320 Grade L7 Heavy Hex Bolt Size Chart

| Diameter | Diameter in mm | Diameter in inch | Nut Sizes |

|---|---|---|---|

| M12 | 12 | 0.4724 | 19 |

| M18 | 18 | 0.7087 | 27 |

| M16 | 16 | 0.6299 | 24 |

| M10 | 10 | 0.3937 | 17 |

| M14 | 14 | 0.5512 | 22 |

| M20 | 20 | 0.7874 | 30 |

| M24 | 24 | 0.9449 | 36 |

| M33 | 33 | 1.2992 | 50 |

| M22 | 22 | 0.8661 | 32 |

| M27 | 27 | 1.063 | 41 |

| M30 | 30 | 1.1811 | 46 |

| M39 | 39 | 1.5354 | 60 |

| M45 | 45 | 1.7717 | 70 |

| M36 | 36 | 1.4173 | 55 |

| M42 | 42 | 1.6535 | 65 |

| M52 | 52 | 2.0472 | 80 |

| M64 | 64 | 2.5197 | 95 |

| M48 | 48 | 1.8898 | 75 |

| M56 | 56 | 2.2047 | 85 |

| M60 | 60 | 2.3622 | 90 |

| M72 | 72 | 2.8346 | 105 |

| M68 | 68 | 2.6772 | 100 |

| M76 | 76 | 2.9921 | 110 |

| M80 | 80 | 3.1496 | 115 |

ASTM A320 Grade L7m Bolts Torque Chart

| BOLT DIA |

Torque FT-LBS | ||

|---|---|---|---|

| 30% Initial Torque |

70% Torque |

100% Final Torque |

|

| 1/2 | 16 | 36 | 52 |

| 5/8 | 31 | 73 | 104 |

| 3/4 | 55 | 129 | 184 |

| 1 | 107 | 249 | 356 |

| 1.1/8 | 127 | 297 | 424 |

| 1.1/4 | 179 | 417 | 596 |

| 1.1/2 | 246 | 574 | 821 |

| 1.9/16 | 168 | 392 | 560 |

| 1.3/4 | 240 | 561 | 801 |

| 1.7/8 | 298 | 696 | 994 |

| 2.1/4 | 529 | 1234 | 1762 |

| 2.1/2 | 733 | 1709 | 2442 |

| 2.3/4 | 986 | 2300 | 3285 |

| BOLT DIA |

Torque Nm | ||

|---|---|---|---|

| 30% Initial Torque |

70% Torque |

100% Final Torque |

|

| 9/16 | 31 | 72 | 102 |

| 5/8 | 42 | 99 | 141 |

| 3/4 | 75 | 175 | 249 |

| 7/8 | 96 | 225 | 321 |

| 1.1/8 | 172 | 403 | 575 |

| 1.1/4 | 243 | 565 | 808 |

| 1.1/2 | 334 | 778 | 1113 |

| 1.9/16 | 228 | 531 | 759 |

| 1.5/8 | 259 | 603 | 862 |

| 1.7/8 | 404 | 944 | 1348 |

| 2 | 496 | 1157 | 1653 |

| 2.1/4 | 717 | 1673 | 2389 |

| 2.3/4 | 1337 | 3118 | 4454 |

| 3 | 1748 | 4078 | 5826 |

A320 Grade L7 Hex Head Bolt Weight Chart

| Diameter (inches) | Length (inches) | Weight (lbs/bolt) |

|---|---|---|

| 1/4″ | 1 | 0.02 |

| 1/4″ | 2 | 0.03 |

| 3/8″ | 1 | 0.04 |

| 3/8″ | 2 | 0.08 |

| 1/2″ | 1 | 0.1 |

| 1/2″ | 2 | 0.2 |

| 5/8″ | 2 | 0.4 |

| 5/8″ | 4 | 0.8 |

| 3/4″ | 2 | 0.6 |

| 3/4″ | 4 | 1.2 |

| 1″ | 4 | 2.0 |

| 1″ | 6 | 3.0 |

Applications of ASTM A325 Bolts

- Oil & Gas Processing

- Petrochemical & Chemical Plants

- Refrigeration & Cryogenic Systems

- Valves & Flanges for Low-Temperature Service

- Pressure Vessels

Related Products

Frequently Asked Questions About ASTM A320 L7 Bolts

What is A320 L7 bolt material?

ASTM A320 Grade L7 is a specification for high-tensile 4140 alloy steel bolting. It’s designed for low-temperature service and covers bars, bolts, screws, and studs.

What is SA 320 L7 material equivalent to?

ASTM A320 Grade L7 is typically based on AISI 4140/4142 alloy steel. Its closest equivalent is its ASME designation, SA320 Grade L7. It is not equivalent to stainless steel high-temperature grades like B638 Grade 660.

What is the difference between ASTM A320 L7 and A193 B7?

A320 L7 shares chemical properties with A193 B7 but is specifically for low-temperature use. L7 requires mandatory Charpy V-Notch impact testing at -101°C (-150°F).

What is the Difference Between Astm A320 L7 and L7m Bolts?

Both grades have similar chemical bases, but L7 is heat-treated to achieve higher strength than L7M. L7M has modified requirements for use in environments needing enhanced resistance to stress corrosion cracking.

Can ASTM A320 L7 Bolts Be Heat Treated?

Yes, ASTM A320 L7 bolts can be heat treated to achieve the necessary mechanical properties and strength specified by the standard.

Can ASTM A320 L7 Bolts Be Coated for Corrosion Protection?

Yes, L7 bolts can be coated for protection. Common coatings include Hot-Dip Galvanizing, Zinc Plating, Cadmium Plating, and various Epoxy/Paint finishes.