The ASTM A325 specification, as defined under the ASTM standard, regulates high-strength structural bolts, which are sold in both the metric and imperial size, which are specifically aimed at steel-to-steel connection in structural works. These bolts have a diameter of between 1/2 to 1-1/2 and are made of quenched and tempered medium-carbon or alloy steel in order to attain the required mechanical strength. The standard is the only requirement of the desired configuration of the bolt with a heavy hex head, full body diameter, and an overall length of generally short length.

The specification lists two categories of quenched and tempered structural bolting fasteners. Type 1 material consists of high-strength plain carbon or alloy steel (with boron variants) that is heat treated, and the minimum tensile strength of 105 ksi is needed, along with a minimum yield of 81 ksi and a maximum hardness of 25-35 HRC. Weathering steel is heat-treated type 3. Although it has a comparable strength profile as Type 1, it has a high level of corrosion protection which makes it more appropriate to be used in wet or adverse weather conditions.

ASTM A325 Structural Bolts Suppliers

Jade Special metals is one of the pioneering manufacturers and distributors of ASTM bolts, specifically ASTM A325 structural bolts with a tremendous range of types and grades to meet the challenging structures of use. We have high strength fasteners such as A325 anchor bolts and other finished bolts such as the A325 hot-dipped galvanized bolts which are corrosion resistant. You may also approach us today to enquire more about our various product types, grades, and inventory levels as well as competitive prices.

Looking to buy Carbon Steel Fasteners?

Check Alloy Steel Bolts & Carbon Steel Bolts Price List in India

Nuts Weight Chart

ASTM A307 Grades

| Types | Details |

|---|---|

| TYPE 1 | Medium carbon, carbon boron, or medium carbon alloy steel. |

| TYPE 2 | Withdrawn November 1991. |

| TYPE 3 | Weathering steel. |

| T | Fully threaded A325.(Restricted to 4 times the diameter in length) |

| M | Metric A325. |

Table of Contents

- Types of ASTM A325 Fasteners

- ASTM A325 Structural Bolts Specifications

- ASTM A325 Bolt Chemical Composition

- ASTM A325 Bolts Mechanical Properties

- ASTM A325 Structural Bolts Mechanical Characteristics

- Equivalent Grade of A325 Fasteners

- A325 Structural Bolts Coating

- ASTM A325 Bolt Dimensions Chart

- ASTM A325 Hex Bolts Dimensions

- ASTM A325 Heavy Hex Bolt Tolerance Chart

- A325 Galvanized Bolts Torque Chart

- ASTM A325 Bolts Inventory

- Applications of ASTM A325 Bolts

Types of ASTM A325 Fasteners

ASTM A325 Bolts And Nuts

ASTM A325 Carriage Bolt

ASTM A325 Heavy Hex Bolts

ASTM A325 Countersunk Bolts

ASTM A325 Stud Bolts

ASTM A325 Hex Bolt

ASTM A325 Anchor Bolts

ASTM A325 Heavy Hex Structural Bolts

ASTM A325 Bolt Washer

ASTM A325 U Bolt

ASTM A325 Type 1 Bolts

ASTM A325 Type 3 Bolts

ASTM A325 Structural Bolts Specifications

| Property | Details |

|---|---|

| ASTM A325 Fasteners Sizes |

Manufacturing M2, M3, M3.5, M4, M5, M6, M8, M10, M12, M14, M16, M18, M20, M22, M24, M27, M30, M33, M36, M42, M45, M48 to M160 and Custom Metric ASTM A325 Structural Bolts |

| A325 Type 1 Bolts Size Metric |

|

| ASTM A325 Hex Bolts Size Inch |

|

| Standard |

Manufacturer of ASTM A325 Structural Bolts as per IS, ANSI, ASTM, DIN, ISO, JIS, GB, ASME, BS, UNI, CSN, EU, IFI, PN, and all International Standards

|

| ASTM A325 Structural Bolts Length | 3 mm to 200 mm |

| Grade A325 Bolts & Screws US Threads | METRIC, BSW, BSF, Unified national coarse (UNC), Unified national fine (UNF), Unified national extra fine (UNEF), UNJC and UNJF threads, UNK threads, UNR threads, Constant-pitch threads |

| ASTM A325 Structural Bolts UTS – Unified Thread Standard | UNC, UNF, NPT, UNS, UNEF, NPTF |

| ASTM A325 Bolts Head drive | Phillips/Slot, Phillips, Slotted, Six-Lobe, etc |

ASTM A325 Bolt Chemical Composition

| Heat Analysis | 120ksi, % | 150ksi, % |

|---|---|---|

| Carbon | 0.30 – 0.52 | 0.30 – 0.48* |

| Manganese | 0.60 min | 0.60 min |

| Phosphorus | 0.035 max | 0.035 max |

| Sulfur | 0.040 max | 0.040 max |

| Silicon | 0.15 – 0.30 | – |

| Boron | 0.003 max | 0.003 max |

| Copper | – | – |

| Nickel | – | – |

| Chromium | – | – |

| Molybdenum | – | – |

| *Carbon 0.35-0.53% for 1-1/2” A490/150ksi bolts | ||

ASTM A325 Bolts Mechanical Properties

| Size | Tensile, ksi | Yield, ksi | Elong. %, min | RA %, min |

|---|---|---|---|---|

| 1⁄2 – 1 | 120 min | 92 min | 14 | 35 |

| 11⁄8 – 11⁄2 | 105 min | 81 min | 14 | 35 |

ASTM A325 Structural Bolts Mechanical Characteristics

| Grade | Size | Tensile ksi min | Yield ksi min |

|---|---|---|---|

| A325 | 1/2″ – 1 | 120 | 92 |

| 1 1/8 – 1 1/2 | 105 | 81 | |

| A490 | 1/2 – 1 1/2 | 150 | 130 |

| A193 B7 | Up to 2 1/2 | 125 | 105 |

| 2 5/8 – 4 | 115 | 95 |

Equivalent Grade of A325 Fasteners

| Standard | Equivalent Grade |

|---|---|

| ISO | Grade 8.8S |

| DIN | DIN 6914 |

| BS | BS 4395-1 |

| New ASTM | F3125 Grade A325 |

A325 Structural Bolts Coating

| Bolt Specification | F2329 Hot Dip Galvanizing | B695 Mechanical Galvanizing | F1136 Zinc/ Aluminum (Geomet) | F2833 Zinc/ Aluminum |

|---|---|---|---|---|

| A325 | Approved | Class 55 | Grade 3 | Grade 1 |

| F1852 | N.A. | Class 55 | N.A. | N.A. |

| A490 | N.A. | N.A. | Grade 3 | Grade 1 |

| F2280 | N.A. | N.A. | N.A. | N.A. |

| *Other coatings may be used on 120ksi/A325 fasteners depends upon purchaser and user. N.A. – Not Approved | ||||

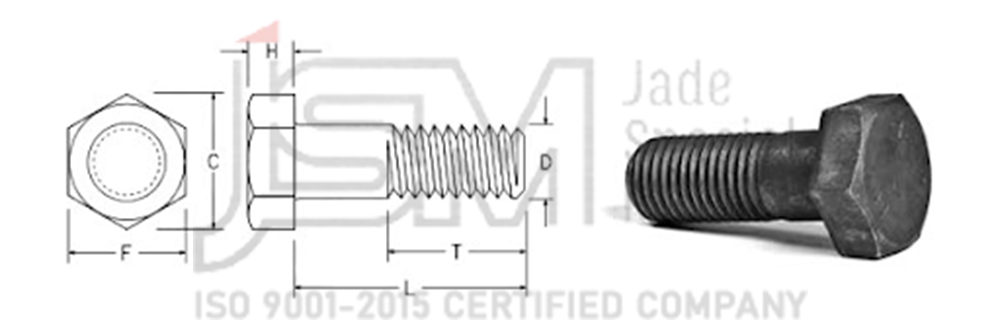

ASTM A325 Bolt Dimensions Chart

| Bolt Diameter | D | F | C | H | T | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Body Diameter | Width Across Flats | Width Across Corners | Height | Thread Length | ||||||

| Max | Basic | Max | Min | Max | Min | Basic | Max | Min | Basic | |

| 7⁄8 | 0.895 | 17⁄16 | 1.438 | 1.394 | 1.660 | 1.589 | 35⁄64 | 0.563 | 0.531 | 1.50 |

| 5⁄8 | 0.642 | 11⁄16 | 1.062 | 1.031 | 1.227 | 1.175 | 25⁄64 | 0.403 | 0.378 | 1.25 |

| 3⁄4 | 0.768 | 11⁄4 | 1.250 | 1.212 | 1.443 | 1.383 | 15⁄32 | 0.483 | 0.455 | 1.38 |

| 1⁄2 | 0.515 | 7⁄8 | 0.875 | 0.850 | 1.010 | 0.969 | 5⁄16 | 0.323 | 0.302 | 1.00 |

| 13⁄8 | 1.404 | 23⁄16 | 2.188 | 2.119 | 2.526 | 2.416 | 27⁄32 | 0.878 | 0.810 | 2.25 |

| 1 | 1.022 | 15⁄8 | 1.625 | 1.575 | 1.876 | 1.796 | 39⁄64 | 0.627 | 0.591 | 1.75 |

| 11⁄4 | 1.277 | 2 | 2.00 | 1.938 | 2.309 | 2.209 | 25⁄32 | 0.813 | 0.749 | 2.00 |

| 11⁄8 | 1.149 | 113⁄16 | 1.812 | 1.756 | 2.093 | 2.002 | 11⁄16 | 0.718 | 0.658 | 2.00 |

| 11⁄2 | 1.531 | 23⁄8 | 2.375 | 2.300 | 2.742 | 2.622 | 15⁄16 | 0.974 | 0.902 | 2.25 |

| Dimensions per ASME B18.2.6 2011 | ||||||||||

ASTM A325 Hex Bolts Dimensions

| Bolt Diameter | D | F | C | H | T | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Body Diameter | Width Across Flats | Width Across Corners | Height | Thread Length | ||||||

| Max | Basic | Max | Min | Max | Min | Basic | Max | Min | Basic | |

| 7⁄8 | 0.895 | 17⁄16 | 1.438 | 1.394 | 1.660 | 1.589 | 35⁄64 | 0.563 | 0.531 | 1.50 |

| 5⁄8 | 0.642 | 11⁄16 | 1.062 | 1.031 | 1.227 | 1.175 | 25⁄64 | 0.403 | 0.378 | 1.25 |

| 3⁄4 | 0.768 | 11⁄4 | 1.250 | 1.212 | 1.443 | 1.383 | 15⁄32 | 0.483 | 0.455 | 1.38 |

| 1⁄2 | 0.515 | 7⁄8 | 0.875 | 0.850 | 1.010 | 0.969 | 5⁄16 | 0.323 | 0.302 | 1.00 |

| 13⁄8 | 1.404 | 23⁄16 | 2.188 | 2.119 | 2.526 | 2.416 | 27⁄32 | 0.878 | 0.810 | 2.25 |

| 1 | 1.022 | 15⁄8 | 1.625 | 1.575 | 1.876 | 1.796 | 39⁄64 | 0.627 | 0.591 | 1.75 |

| 11⁄4 | 1.277 | 2 | 2.00 | 1.938 | 2.309 | 2.209 | 25⁄32 | 0.813 | 0.749 | 2.00 |

| 11⁄8 | 1.149 | 113⁄16 | 1.812 | 1.756 | 2.093 | 2.002 | 11⁄16 | 0.718 | 0.658 | 2.00 |

| 11⁄2 | 1.531 | 23⁄8 | 2.375 | 2.300 | 2.742 | 2.622 | 15⁄16 | 0.974 | 0.902 | 2.25 |

| Dimensions per ASME B18.2.6 2011 | ||||||||||

“Contact Jade Special Metals today with your requirement for ASTM A325 Bolts. We assure you of the best quote.

ASTM A325 Heavy Hex Bolt Tolerance Chart

| Bolt Diameter | Bolt Lengths Thru 6″ | Bolt Lengths Over 6″ |

|---|---|---|

| 1/2″ | -0.12 | -0.19 |

| 3/4″ | -0.19 | -0.25 |

| 7/8″ | -0.19 | -0.25 |

| 5/8″ | -0.12 | -0.25 |

| 1-3/8″ | -0.25 | -0.25 |

| 1-1/2″ | -0.25 | -0.25 |

| 1″ | -0.19 | -0.25 |

| 1-1/8″ | -0.25 | -0.25 |

| 1-1/4″ | -0.25 | -0.25 |

A325 Galvanized Bolts Torque Chart

| Size of A325 Bolt | TPI | Tension | Tightening Torque Range (ft lbs) (Min – Max) | ||

|---|---|---|---|---|---|

| Min | Max | Galv+Waxed | Plain | ||

| 1⁄2 | 13 | 12,000 | 14,000 | 50 – 58 | 100 – 117 |

| 5⁄8 | 11 | 19,000 | 23,000 | 99 – 120 | 198 – 240 |

| 3⁄4 | 10 | 28,000 | 34,000 | 175 – 213 | 350 – 425 |

| 7⁄8 | 9 | 39,000 | 47,000 | 284 – 343 | 569 – 685 |

| 1 | 8 | 51,000 | 61,000 | 425 – 508 | 850 – 1,017 |

| 11⁄8 | 7 | 64,000 | 77,000 | 600 – 722 | 1,200 – 1,444 |

| 11⁄4 | 7 | 81,000 | 98,000 | 844 – 1,021 | 1,687 – 2,042 |

| 13⁄8 | 6 | 97,000 | 117,000 | 1,111 – 1,341 | 2,223 – 2,681 |

| 11⁄2 | 6 | 118,000 | 143,000 | 1,475 – 1,788 | 2,950 – 3,575 |

Applications of ASTM A325 Bolts

- Structural Steel

- Bridge Construction

- Towers & Transmission

- Heavy Machinery & Equipment

- Industrial & Infrastructure

- Mining Operations

Related Products

Frequently Asked Questions About ASTM A325 Bolts

What is the ASTM A325 bolt standard?

ASTM A325 is a standard ASTM International standard referred to as the Standard Specification of Structural Bolts, Steel, Heat Treated, 120/105 ksi Minimum tensile Strength. This is a specification that establishes the mechanical properties of heavy hex structural bolts with a diameter between 112 and 13 mm (12 to 18 mm) in diameter.

What is the A325 used for?

The bolts of type A325 are mainly applied during structural connections and high tensile strength and fatigue resistance. They play a critical role in the connections of heavy load-carrying members in the infrastructure construction works such as bridges and massive buildings.

How to measure A325 bolts?

The length of the heavy HEX A245 bolt is measured with the help of bolt head straight to the end of the threaded tip.

What is the minimum tensile strength of ASTM A325 bolts?

ASTM A325 bolts have a minimum tensile strength which is related to the diameter of the bolts. At sizes between 1/2 and 1, the bolts must have a tensile strength of 120ksi in minimum and reduction in area of 35. In the larger sizes, 11/8 to 11/2, the minimum tensile strength needed is a little less at 105ksi, and the minimum area reduction is 35.

What is the main difference between an A325 and an A490 bolt?

The minimum tensile strength (A490) is higher (150 ksi) than A325 bolts (120 ksi). A490 bolts are applied when higher strength is needed, whereas A325 bolts can be used to most typical structural steel connections.