ASTM F594 Specification for Stainless Steel Nuts

ASTM F467 specification is a standard in the industry to produce commercial non-ferrous wrought nuts. These materials are iron-free by definition and hence they are necessary in special industrial uses, either where non-magnetic behavior is needed or corrosion resistance is required to the utmost. A wide variety of shapes is covered by this specification, including ASTM F467 Hex Nuts, square nuts, coupling nuts and lock nuts, which are normally produced in nominal thread diameters of M6 to M36.

These fasteners can be customized to fit special needs in the environment since different Astm f467 materials have varying physical properties. As an illustration, the use of aluminum will yield an extremely light fastener, but when a brass alloy is used, corrosion protection against seawater is achieved which is required in marine engineering. All materials such as ASTM F467 Grade 5 Nuts are tested to assure reliability in chemical composition, hardness, proof stress and tensile strength. For a detailed technical breakdown, engineers often refer to the astm f467 pdf for compliance and manufacturing tolerances.

ASME SF467 Nuts Supplier and Exporter in India

Jade Alloys is a premier industry leader specializing in the supply of top-tier non-ferrous fasteners, including high-performance ASTM F467 Bolts. By utilizing high-grade nickel and copper alloys, we manufacture durable ASTM F467 Lock Nuts and Nyloc Nuts that offer superior longevity. Our production line strictly adheres to the ASME SF467 Nuts specification, ensuring that every component meets the most demanding engineering standards for global applications.

The mechanical prowess of ASTM F467 Metric Nuts is defined by high proof load capacities and remarkable mechanical integrity. In addition to metric sizes, we provide ASME SF467 Dome Nuts in a broad dimensional range from 1/4” to 1-1/2”. These fasteners are indispensable in harsh environments such as Acid Processing Plants, Oil Refineries, and Gas Scrubbing Systems. Whether you are reviewing an Astm f467 nuts chart for sizing or searching for an Astm f467 nuts equivalent in specialized alloys, our inventory is designed to meet your specific needs.

Our ability to customize alloy compositions and surface finishes ensures that our ASTM F467 Square Nuts meet the precise needs of specialized machinery and critical infrastructure projects worldwide.

Looking to buy Nuts?

Check Stainless Steel Nuts, Alloy Steel Nuts & Carbon Steel Nuts Price List in India

Nuts Weight Chart

Quick Section Links

- ASTM F467 Nuts Types

- ASTM F467 Nuts Specifications

- ASTM F467 Nuts Material Grades

- ASTM F467 Nuts Size Chart

- ASTM F467 Hex Nut Dimensions

- ASTM F467 Heavy Hex Nuts Dimension

- F467 Nuts Chemical Composition

- ASTM F467 Mechanical Properties

- ASTM F467 Nuts Applications & Uses

- Testing Equipment for ASTM F467 Nuts

- ASTM F467 Nuts Price In India

ASTM F467 Nuts Types

ASTM F467 Nuts Specifications

| Feature | Details |

|---|---|

| Standards | ASTM F467 / ASME SF467 |

| Dimensions | ASME B18.2.1, B18.2.2, B18.3 |

| Size Range | M6 to M36 (Metric), 1/4″ to 1-1/2″ (Inch) |

| Threads | ASME B1.1 2A/3A Unified & B1.13M 6h Metric Coarse |

| Coatings | Black Oxide, Cadmium, Galvanized, Teflon, Xylan, Zinc |

| Certifications | PED 97/23/EC, NACE MR0175 / ISO 15156 Compliance |

ASTM F467 Nuts Material Grades

The ASTM F467 specification is primarily focused on non-ferrous alloys; however, in industrial procurement, these nuts are often cross-referenced or used alongside high-performance steel and nickel grades to ensure compatibility across complex assemblies.

Below is the comprehensive material breakdown for ASTM F467 equivalent and related fastener grades:

| Material Category | Common Grades & Specifications |

|---|---|

| Nickel Alloys | Monel 400 (UNS 4400), Inconel 600/601/625/825, Hastelloy C276, Nickel 200/201, Alloy 20 |

| Stainless Steel | AISI 304/304L, 316/316L, 310, 317L, 321, 347, 410, 420, 904L |

| Duplex & Super Duplex | UNS S31803, S32205 (2205), S32750 (2507), S32760, S31254 (6mo) |

| Alloy Steel | ASTM A194/A193 Grades B7, B7M, B16, B6, 2H, 2HM, Grade 6 |

| Carbon Steel | ASTM A307 Grades A & B |

ASTM F467 Nuts Size Chart

Refer to this Astm f467 nuts chart for standard metric sizing.

| Nuts Size (mm) | Diameter* (mm) | Height (mm) | ||

|---|---|---|---|---|

| Hex Nuts | Jam Nuts | Nylock Nuts | ||

| 2 | 4 | 1.6 | 1.2 | – |

| 2.5 | 5 | 2 | 1.6 | – |

| 3 | 5.5 | 2.4 | 1.8 | 4 |

| 4 | 7 | 3.2 | 2.2 | 5 |

| 5 | 8 | 4 | 2.7 | 5 |

| 6 | 10 | 5 | 3.2 | 6 |

| 7 | 11 | 5.5 | 3.5 | – |

| 8 | 13 | 6.5 | 4 | 8 |

| 10 | 17 | 8 | 5 | 10 |

| 12 | 19 | 10 | 6 | 12 |

| 14 | 22 | 11 | 7 | 14 |

| 16 | 24 | 13 | 8 | 16 |

| 18 | 27 | 15 | 9 | 18.5 |

| 20 | 30 | 16 | 10 | 20 |

| * This is the diameter across the flats. It is also the size of wrench to use. | ||||

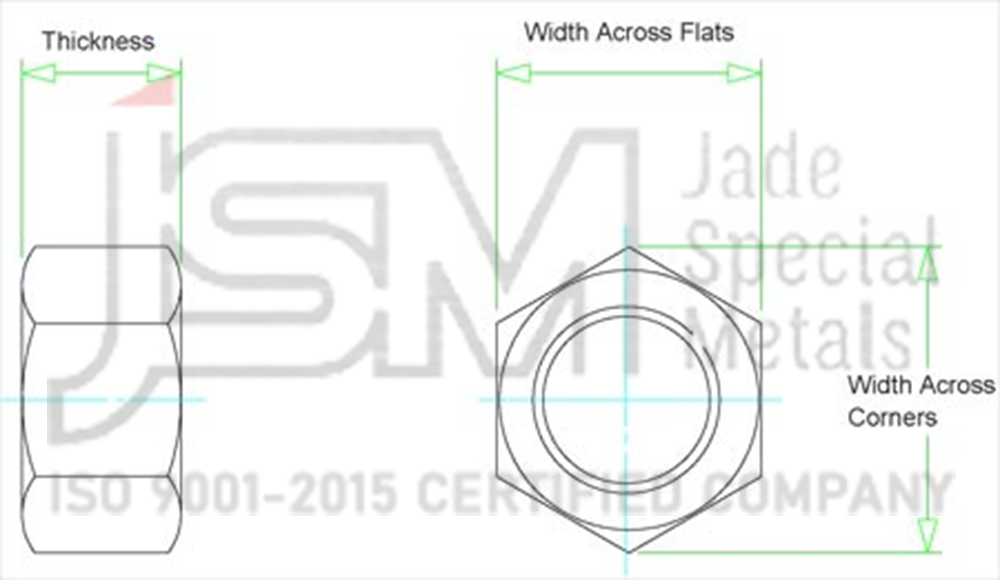

ASTM F467 Hex Nut Dimensions

| Nominal Size or Basic Major Thread Diameter | F | G | H | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Width Across Flats | Width Across Corners | Thickness | |||||||

| Basic | Max | Min | Max | Min | Basic | Max | Min | ||

| 1/4 | .2500 | 7/16 | .438 | .428 | .505 | .488 | 7/32 | .226 | .212 |

| 5/16 | .3125 | 1/2 | .500 | .489 | .577 | .557 | 17/64 | .273 | .258 |

| 3/8 | .3750 | 9/16 | .562 | .551 | .650 | .628 | 21/64 | .337 | .479 |

| 7/16 | .4375 | 11/16 | .688 | .675 | .794 | .768 | 3/8 | .385 | .365 |

| 1/2 | .5000 | 3/4 | .750 | .736 | .866 | .840 | 7/16 | .448 | .427 |

| 9/16 | .5625 | 7/8 | .875 | .861 | 1.010 | .982 | 31/64 | .496 | .473 |

| 5/8 | .6250 | 15/16 | .938 | .922 | 1.083 | 1.051 | 35/64 | .559 | .535 |

| 3/4 | .7500 | 1-1/8 | 1.125 | 1.088 | 1.299 | 1.240 | 41/64 | .665 | .617 |

| 7/8 | .8750 | 1-5/16 | 1.312 | 1.269 | 1.516 | 1.447 | 3/4 | .776 | .724 |

| 1 | 1.0000 | 1-1/2 | 1.500 | 1.450 | 1.732 | 1.653 | 55/64 | .887 | .831 |

| 1-1/8 | 1.1250 | 1-11/16 | 1.688 | 1.631 | 1.949 | 1.859 | 31/32 | .999 | .939 |

| 1-3/8 | 1.3750 | 2-1/16 | 2.062 | 1.994 | 2.382 | 2.273 | 1-11/64 | 1.206 | 1.138 |

| 1-1/2 | 1.500 | 2-1/4 | 2.250 | 2.175 | 2.598 | 2.480 | 1-9/32 | 1.ASTM A194 GR. 8 | 1.245 |

| 1-5/8 | 1.6250 | 2-7/16 | 2.438 | 2.356 | 2.815 | 2.686 | 1-25/64 | 1.429 | 1.353 |

| 1-3/4 | 1.7500 | 2-5/8 | 2.625 | 2.538 | 3.031 | 2.893 | 1-1/2 | 1.540 | 1.460 |

| 2 | 2.0000 | 3 | 3.000 | 2.900 | 3.464 | 3.306 | 1-23/32 | 1.763 | 1.675 |

| 2-1/4 | 2.2500 | 3-3/8 | 3.375 | 3.263 | 3.897 | 3.719 | 1-15/16 | 1.986 | 1.890 |

| 2-1/2 | 2.5000 | 3-3/4 | 3.750 | 3.625 | 4.330 | 4.133 | 2-5/32 | 2.209 | 2.105 |

| 2-3/4 | 2.7500 | 4-1/8 | 4.125 | 3.988 | 4.763 | 4.546 | 2-3/8 | 2.431 | 2.319 |

ASTM F467 Heavy Hex Nuts Dimension

| Nominal Size or Basic Major Thread Diameter | F | G | H | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Width Across Flats | Width Across Corners | Thickness | |||||||

| Basic | Max | Min | Max | Min | Basic | Max | Min | ||

| 1/4 | .2500 | 1/2 | .500 | .488 | .577 | .556 | 15/64 | .250 | .218 |

| 5/16 | .3125 | 9/16 | .562 | .546 | .650 | .622 | 19/64 | .314 | .280 |

| 3/8 | .3750 | 11/16 | .688 | .669 | .794 | .763 | 23/64 | .377 | .341 |

| 7/16 | .4375 | 3/4 | .750 | .728 | .866 | .830 | 27/64 | .441 | .403 |

| 1/2 | .5000 | 7/8 | .875 | .850 | 1.010 | .969 | 31/64 | .504 | .464 |

| 9/16 | .5625 | 15/16 | .938 | .909 | 1.083 | 1.037 | 35/64 | .568 | .526 |

| 5/8 | .6250 | 1-1/16 | 1.062 | 1.031 | 1.227 | 1.175 | 39/64 | .631 | .587 |

| 3/4 | .7500 | 1-1/4 | 1.250 | 1.212 | 1.443 | 1.382 | 47/64 | .758 | .710 |

| 7/8 | .8750 | 1-7/16 | 1.438 | 1.394 | 1.660 | 1.589 | 55/64 | .885 | .833 |

| 1 | 1.0000 | 1-5/8 | 1.325 | 1.575 | 1.876 | 1.796 | 63/64 | 1.012 | .956 |

| 1-1/8 | 1.1250 | 1-13/16 | 1.812 | 1.756 | 2.093 | 2.002 | 1-7/64 | 1.139 | 1.079 |

| 1-1/4 | 1.2500 | 2 | 2.000 | 1.938 | 2.309 | 2.209 | 1-7/32 | 1.251 | 1.187 |

| 1-3/8 | 1.3750 | 2-3/16 | 2.188 | 2.119 | 2.526 | 2.416 | 1-11/32 | 1.378 | 1.460 |

| 1-1/2 | 1.5000 | 2-3/8 | 2.375 | 2.300 | 2.742 | 2.622 | 1-15/32 | 1.505 | 1.433 |

| 1-5/8 | 1.6250 | 2-9/16 | 2.562 | 2.481 | 2.959 | 2.828 | 1-19/32 | 1.632 | 1.556 |

| 1-3/4 | 1.7500 | 2-3/4 | 2.750 | 2.662 | 3.175 | 3.035 | 1-23/32 | 1.759 | 1.679 |

| 2 | 2.0000 | 3-1/8 | 3.125 | 3.025 | 3.608 | 3.449 | 1-31/32 | 2.013 | 1.925 |

| 2-1/4 | 2.2500 | 3-1/2 | 3.500 | 3.388 | 4.041 | 3.862 | 2-13/64 | 2.251 | 2.155 |

| 2-1/2 | 2.5000 | 3-7/8 | 3.875 | 3.750 | 4.474 | 4.275 | 2-29/64 | 2.505 | 2.401 |

| 2-3/4 | 2.7500 | 4-1/4 | 4.250 | 4.112 | 4.907 | 4.688 | 2-45/64 | 2.759 | 2.647 |

| 3 | 3.0000 | 4-5/8 | 4.625 | 4.475 | 5.340 | 5.102 | 2-61/64 | 3.013 | 2.893 |

| 3-1/4 | 3.2500 | 5 | 5.000 | 4.838 | 5.774 | 5.515 | 3-3/16 | 3.252 | 3.124 |

| 3-1/2 | 3.5000 | 5-3/8 | 5.375 | 5.200 | 6.207 | 5.928 | 3-7/16 | 3.506 | 3.370 |

| 3-3/4 | 3.7500 | 5-3/4 | 5.750 | 5.562 | 6.640 | 6.341 | 3-11/16 | 3.670 | 3.616 |

| 4 | 4.0000 | 6-1/8 | 6.125 | 5.925 | 7.073 | 6.755 | 3-15/16 | 4.014 | 3.862 |

F467 Nuts Chemical Composition

| Composition, % Copper and Copper Base Alloys | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| UNS Designation | Alloy | General Name | Aluminum | Copper, min | Iron, max | Manganese, max | Nickel, max | Phosphorus | Silicon | Zinc, maxA | Lead, max | Tin | Arsenic, max |

| C11000 | 110 | ETP Copper | — | 99.9 | — | — | — | — | — | — | — | — | — |

| C26000 | 260 | Brass | — | 68.5 – 71.5 | 0.05 | — | — | — | — | balance | 0.07 | — | — |

| C27000 | 270 | Brass | — | 63.0 – 68.5 | 0.07 | — | — | — | — | balance | 0.10 | — | — |

| C46200 | 462 | Naval Brass | — | 62.0 – 65.0 | 0.10 | — | — | — | — | balance | 0.20 | 0.50 – 1.00 | — |

| C46400 | 464 | Naval Brass | — | 59.0 – 62.0 | 0.10 | — | — | — | — | balance | 0.20 | 0.50 – 1.00 | — |

| C51000 | 510 | Phosphor Bronze | — | balanceA | 0.10 | — | — | 0.03 – 0.35 | — | 0.30 | 0.05 | 4.20 – 5.80 | — |

| C61300 | 613 | Aluminum Bronze | 6.0 – 7.5 | B | 2.0 – 3.0 | 0.10 | 0.15C | 0.015 | 0.10 | 0.05 | 0.01 | 0.20 – 0.50 | — |

| C61400 | 614 | Aluminum Bronze | 6.0 – 8.0 | 88.0D | 1.5 – 3.5 | 1.00 | — | — | — | — | — | — | — |

| C63000 | 630 | Aluminum Bronze | 9.0 – 11.0 | 78.0D | 2.0 – 4.0 | 1.50 | 4.0 – 5.5 | — | 0.25 max | — | — | 0.20 max | — |

| C64200 | 642 | Aluminum Silicon Bronze | 6.3 – 7.6 | 88.65D | 0.30 | 0.10 | 0.25 | 1.50 – 2.20E | 0.50 | 0.05 | 0.20 max | 0.15 | |

| C65100 | 651 | Silicon Bronze | — | 96.0D | 0.80 | 0.70 | — | — | 0.8 – 2.0 | 1.50 | 0.05 | — | — |

| C65500 | 655 | Silicon Bronze | — | 94.8D | 0.80 | 1.50 | 0.60 | — | 2.8 – 3.8 | 1.50 | 0.05 | — | — |

| C66100 | 661 | Silicon Bronze | 0.25 max | 94.0D | 0.25 | 1.50 | — | — | 2.8 – 3.5 | 1.50 | 0.20 – 0.80 | — | — |

| C67500 | 675 | Manganese Bronze | — | 57.0 – 60.0 | 0.8 – 2.0 | 0.05 – 0.50 | — | — | — | balance | 0.20 | 0.50 – 1.50 | — |

| C71000 | 710 | Cupro Nickel | — | 74.0D | 0.60 | 1.00 | 19.0 – 23.0C | — | 1.00 | 0.05 | — | — | |

| C71500 | 715 | Cupro Nickel | — | 65.0D | 0.40 – 0.70 | 1.00 | 29.0 – 33.0C | — | — | 1.00 | 0.05 | — | |

ASTM F467 Mechanical Properties

| Alloy | Mechanical Property Marking | Nominal Thread Diameter, inch | HardnessA | Proof Stress, min, ksi |

|---|---|---|---|---|

| Copper | ||||

| Cu 110 | F 467A | all | 65 HRF | 30 |

| Cu 260 | F 467AB | all | 55 HRF | 60 |

| Cu 270 | F 467B | all | 55 HRF | 60 |

| Cu 462 | F 467C | all | 65 HRB | 50 |

| Cu 464 | F 467D | all | 55 HRB | 50 |

| Cu 510 | F 467E | all | 60 HRB | 60 |

| Cu 613 | F 467F | all | 70 HRB | 80 |

| Cu 614 | F 467G | all | 70 HRB | 75 |

| Cu 630 | F 467H | all | 85 HRB | 100 |

| Cu 642 | F 467J | all | 75 HRB | 75 |

| Cu 651 | F 467K | all | 75 HRB | 70 |

| Cu 655 | F 467L | all | 60 HRB | 50 |

| Cu 661 | F 467M | all | 75 HRB | 70 |

| Cu 675 | F 467N | all | 60 HRB | 55 |

| Cu 710 | F 467P | all | 50 HRB | 45 |

| Cu 715 | F 467R | all | 60 HRB | 55 |

| Nickel Alloys | ||||

| Ni 59 Grade 1 | F467FN | all | 21 HRC | 120 |

| Ni 59 Grade 2 | F467GN | all | 23 HRC | 135 |

| Ni 59 Grade 3 | F467HN | all | 25 HRC | 160 |

| Ni 59 Grade 4 | F467JN | all | 80 HRB | 100 |

| NI 335 | F 467S | all | 20 HRC | 115 |

| Ni 276 | F 467T | all | 20 HRC | 110 |

| Ni 400 | F 467U | all | 75 HRB | 80 |

| Ni 405 | F 467V | all | 60 HRB | 70 |

| Ni 500 | F 467W | all | 24 HRC | 130 |

| Ni 625 | F 467AC | all | 85 HRB – 35 HRC | 60 |

| Ni 686 Grade 1 | F 467BN | all | 21 HRC | 120 |

| Ni 686 Grade 2 | F 467CN | all | 23 HRC | 135 |

| Ni 686 Grade 3 | F 467DN | all | 25 HRC | 160 |

| Ni 686 Grade 4 | F 467EN | all | 65 HRB – 25 HRC | 100 |

| Aluminum | ||||

| Al 2024 – T4B | F 467X | all | 70 HRB | 55 |

| Al 6061 – T6 | F 467Y | all | 40 HRB | 40 |

| Al 6262 – T9 | F 467Z | all | 60 HRB | 52 |

| Titanium Alloys | ||||

| Ti 1 | F 467AT | all | 140 HV | 40 |

| Ti 2 | F 467BT | all | 150 HV | 55 |

| Ti 4 | F 467CT | all | 200 HV | 85 |

| Ti 5 | F 467DT | all | 30 HRC | 135 |

| Ti 7 | F 467ET | all | 160 HV | 55 |

| Ti 19 | F 467FT | all | 24 HRC | 120 |

| Ti 23 | F 467GT | all | 25 HRC | 125 |

| Ti-5-1-1-1 | F 467AHT | all | 24 HRC | 105 |

ASTM F467 Nuts Applications & Uses

- Power Generation

- Nuclear Energy Sector

- Oil & Gas Industries

- Offshore & Marine Engineering

- Automotive Industry

- Heat Exchangers

- Chemical & Petrochemical Plants

- Electrical & Agricultural Equipment

Testing Equipment for ASTM F467 Nuts

- Coordinate Measuring Machine (CMM)

- Micrometer & Calipers

- Thread Gauges & Plug Gauges

- Surface Roughness Tester

- Image Measuring Instruments

ASTM F594 Nuts Price In India

| Product Description | Price (USD) | Unit |

|---|---|---|

| ASTM F467 Hexagon Nut | $0.01 – $0.50 | Per Piece |

| ASTM F467 Heavy Hex Nut | $0.10 – $1.20 | Per Piece |

| ASTM F467 Coupling Nut | $0.01 – $0.10 | Per Piece |

| ASTM F467 Lock Nut | $1.50 – $2.00 | Per Piece |

| ASTM F467 Hex Flange Nut | $0.10 – $2.00 | Per Piece |

| ASTM F467 Hex Flange Weld Nut | $0.10 – $1.20 | Per Piece |

Related Products

We maintain ready stock of ASTM F467 Hex Nuts, ASTM F467 Heavy Hex Nuts, ASTM F467 Square Nuts, ASTM F467 Lock Nuts, ASTM F467 Self Locking Nuts & ASTM F467 Nylon Insert Nuts. Get in touch with us with your requirement for a quick quote.

Request a Quote