Inconel 625 Round Bars Manufacturer, Supplier & Exporter

Jade Special Metals is a premier manufacturer, supplier, and exporter of high-quality INCONEL 625 ROUND BARS. We specialize in providing robust and reliable Inconel 625 Bar Stock that meets the stringent demands of various industries. Our commitment to excellence ensures that every Alloy 625 Round Bar we deliver adheres to international standards like ASTM B446 and ASME SB446, offering exceptional performance in extreme conditions.

Whether you require standard dimensions or custom-fabricated 625 Round Bar solutions, Jade Special Metals is your trusted partner. We maintain a vast inventory of UNS N06625 products, guaranteeing prompt delivery and competitive price. From aerospace to marine applications, our Alloy 625 Rod provides the strength and corrosion resistance critical for your project’s success.

Quick Section Links

- What is Inconel 625 Round Bar?

- Types of Inconel 625 Round Bars

- Inconel 625 Round Bars Specifications

- Inconel 625 Round Bars Chemical Composition

- Inconel 625 Round Bars Mechanical Properties

- Equivalent Grades for Inconel 625 Round Bars

- Inconel 625 Round Bar Surface Finish

- Inconel 625 Round Bar Weight Chart

- Inconel 625 Bar Tolerances

- Inconel 625 Round Bars Inventory

- Available Stock of Inconel 625 Round Bars

- Applications of Inconel 625 Round Bars

- Why Choose Jade Special Metals for Inconel 625 Round Bars?

- Related Products

- Get a Quote for Inconel 625 Round Bars

What is Inconel 625 Round Bar?

Inconel 625 Round Bar is a highly versatile nickel-chromium-molybdenum alloy renowned for its exceptional combination of high strength, superior fabricability, and outstanding corrosion resistance. Also identified as UNS N06625 or Alloy 625 Rod, this superalloy maintains its robust properties across an incredibly wide temperature range, from cryogenic conditions up to 1800°F (982°C).

The unique metallurgical composition of Alloy 625 Round Bar, particularly its high molybdenum and niobium content, provides a solid-solution stiffening effect on the alloy’s nickel-chromium matrix. This distinct feature eliminates the need for precipitation hardening, simplifying its processing while ensuring its inherent strength. As a result, Inconel 625 Bar Stock offers excellent resistance to a broad spectrum of aggressive corrosive environments, including resistance to pitting, crevice corrosion, intergranular attack, and superior protection against chloride-ion stress-corrosion cracking. Its reliability and longevity make it an indispensable material for the most critical and demanding applications in various industries.

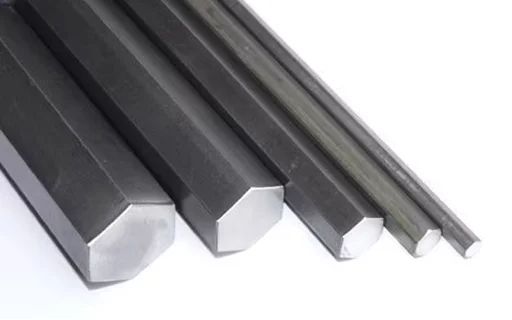

Types of Inconel 625 Round Bars

Inconel 625 Round Bar Specifications

| Specification | Details |

| Standard | ASTM B446, ASME SB446 |

| Designation | UNS N06625, W.Nr. 2.4856 |

| Common Name | Inconel 625, Alloy 625, Nickel 625 |

| Forms | Round, Square, Hex, Flat, Forged Bars |

| Size Range | 3mm to 800mm Diameter |

| Length | 1 to 6 Meters, Custom Cut-to-Length |

| Finish | Black, Bright Polished, Rough Turned, Matt Finish |

| Condition | Annealed, Hot-Finished, Cold-Drawn |

| Certification | Mill Test Certificate (MTC) as per EN 10204 3.1 |

| Testing | NDE, Hardness Test, Tensile Test, Pitting Resistance Test |

“Contact Jade Special Metals today with your requirement for Inconel 625 Round Bars and Alloy 625 Rods. We assure you of the best quote.

Inconel 625 Round Bar Chemical Composition

| Grade | C | Mn | Si | Cu | S | Fe | Mo | Ni | Cr |

| Inconel 625 | 0.10 max | 0.50 max | 0.50 max | – | 0.15 min | 5.0 max | – | 58 min | 20 – 23 |

Inconel Alloy 625 Round Bars Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % |

Equivalent Grades for Inconel 625 Bar

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NA 21 | ХН75МБТЮ | NC22DNB4M | NiCr22Mo9Nb |

Alloy 625 Round Bar Surface finish

| CD | Cold drawn | P | Polished |

| BD | Bright drawn | SRE | Slit rolled edge |

| CG | Centreless ground | HF | Hot finished |

| CF | Cold finished | HRAP | Hot rolled annealed and pickled |

| P&T | Peeled and turned | RT | Rough turned/peeled |

| ST | Smooth turned | PR | Peeled and reeled |

Inconel 625 Round Bar Weight Chart

| Diameter (mm) | Diameter (inches) | Weight ( kg/m ) | Weight (lbs/ft) |

| 3 mm | ~1/8″ | 0.055 | 0.037 |

| 6 mm | ~1/4″ | 0.223 | 0.150 |

| 8 mm | ~5/16″ | 0.398 | 0.267 |

| 10 mm | ~3/8″ | 0.620 | 0.417 |

| 12 mm | ~1/2″ | 0.889 | 0.598 |

| 16 mm | ~5/8″ | 1.578 | 1.061 |

| 20 mm | ~3/4″ | 2.470 | 1.660 |

| 25 mm | ~1″ | 3.871 | 2.600 |

| 30 mm | ~1-3/16″ | 5.548 | 3.729 |

| 40 mm | ~1-1/2″ | 9.872 | 6.634 |

| 50 mm | ~2″ | 15.414 | 10.360 |

| 60 mm | ~2-3/8″ | 22.205 | 14.920 |

| 75 mm | ~3″ | 35.762 | 24.020 |

| 100 mm | ~4″ | 63.340 | 42.560 |

Inconel 625 Bar Tolerances

Cold-Drawn Bar Tolerances

| Section / Shape | Diameter or Width (mm) | Permitted Variation (mm) |

| Round | ≥ 6 to ≤ 18 | +0 to –0.070 |

| > 18 to ≤ 30 | +0 to –0.085 | |

| > 30 to ≤ 50 | +0 to –0.100 | |

| > 50 to ≤ 80 | +0 to –0.120 | |

| Square & Hex | ≥ 6 to ≤ 18 | +0 to –0.090 |

| > 18 to ≤ 30 | +0 to –0.110 | |

| > 30 to ≤ 50 | +0 to –0.130 | |

| > 50 to ≤ 80 | +0 to –0.160 |

Turned Round Bar Tolerances (BS 970-3)

| Diameter (mm) | Permitted Variation (mm) |

| ≥ 6 to ≤ 18 | +0 to –0.070 |

| > 18 to ≤ 30 | +0 to –0.085 |

| > 30 to ≤ 50 | +0 to –0.100 |

| > 50 to ≤ 80 | +0 to –0.120 |

| > 80 to ≤ 120 | +0 to –0.140 |

| > 120 to ≤ 180 | +0 to –0.160 |

Bright Round Bar Tolerances (ISO ‘h’ Series)

| Nominal Size (mm) | h8 | h9 | h11 |

| > 3 to ≤ 6 | +0.018 / 0 | +0.030 / 0 | +0.075 / 0 |

| > 6 to ≤ 10 | +0.022 / 0 | +0.036 / 0 | +0.090 / 0 |

| > 10 to ≤ 18 | +0.027 / 0 | +0.043 / 0 | +0.110 / 0 |

| > 18 to ≤ 30 | +0.033 / 0 | +0.052 / 0 | +0.130 / 0 |

| > 30 to ≤ 50 | +0.039 / 0 | +0.062 / 0 | +0.160 / 0 |

| > 50 to ≤ 80 | +0.046 / 0 | +0.074 / 0 | +0.190 / 0 |

| > 80 to ≤ 120 | +0.054 / 0 | +0.087 / 0 | +0.220 / 0 |

Inconel 625 Round Bars Inventory

Inconel 625 Hex Bar

Inconel 625 Square Bar

Inconel 625 Bright Bar

Inconel 625 Threaded Bar

Inconel 625 Flat Bar

Inconel 625 Rectangular Bar

Available Stock of ASTM B446 Alloy 625 Round Bars

- Inconel 625 Cold Drawn Bars

- Alloy 625 Hexagonal Bar

- 625 Inconel Square Bars

- UNS N06625 Round Bar

- WERKSTOFF NR. 2.4856 Bars

- ASTM B446 Inconel 625 Polished Bar

- Inconel 625 Rectangular Bar

- Inconel 625 Forged Bars

- Alloy 625 Half-Round Bar

- ASTM B446 Type 625 Hex Bar

- 625 Inconel Flat Bar

- UNS N06625 Rods

- WERKSTOFF NR. 2.4856 Triangle Bar

- ASME SB446 Alloy 625 Bright Bar

- ASTM B446 Alloy 625 Precision Ground Bar

- Inconel 625 Bright Round Bar

- Inconel 625 Threaded Bars

- Alloy 625 Precision Ground Stock

- SW 13 Inconel 625 Hex Rod

- SW 17 Inconel 625 Hex Rod

- 625 Inconel Hollow Bar

- Inconel 625 Rods

- UNS N06625 Flat Bars Supplier

- WERKSTOFF NR. 2.4856 Flat Bars

- Inconel Alloy 625 Round Bar

- Alloy 625 Cold Drawn Round Bar

- Inconel 625 Bars Manufacturer

- 625 Inconel Hex Bars

- ASTM B446 Type 625 Cold Rolled Bar

- 625 Inconel Bar Distributor

- UNS N06625 Square Bar Exporter

- WERKSTOFF NR. 2.4856 Bright Bar

- ASTM B446 Type 625 Flat Bar Rolled Edge

- ASME SB446 Inconel 625 Bar

- 2.4856 Inconel Rods

- Alloy 625 Black Bar Stockist

- Inconel 625 Round Bar Price

- Alloy 625 Rebar

- SW 19 Inconel 625 Hex Rod

- SW 24 Inconel 625 Hex Rod

Applications of Inconel 625 Bars

-

- Aerospace: In engine exhaust systems, ducting, and turbine components.

- Chemical Processing: For equipment handling aggressive mixed acids.

- Marine Industry: In propeller blades and subsea hardware requiring saltwater immunity.

- Oil & Gas: For flare stacks, piping, and sour gas processing equipment.

- Nuclear Energy: In critical reactor core and control-rod components.

Why Choose Jade Special Metals for Inconel 625 Round Bar?

- Certified Raw Material: We only use premium quality, fully certified raw materials to manufacture our Inconel 625 Round Bars.

- Extensive Stock: Our large inventory ensures we can meet urgent and bulk requirements with short lead times.

- Competitive Price: As a direct manufacturer and stockist, we eliminate extra costs, offering you a competitive price on all our products.

- Gobal Explorter: With years of experience as an exporter, we can efficiently ship materials to any location worldwide.

- Expert Team: Our knowledgeable staff can provide technical assistance to help you select the right grade and size for your application.

Related Products

Get a Quote for Inconel 625 Round Bars

Ready to enhance your projects with high-quality Inconel 625 Round Bars? Contact Jade Special Metals today for a detailed consultation and a no-obligation quote. Our experts are here to assist you with all your Inconel 625 Bar Stock and Alloy 625 Rod needs, providing the best solutions at competitive prices.

We maintain ready stock of Stainless Steel ASTM F594 Self Locking Nut, ASTM F594 Heavy Hex Nuts, ASTM F594 Self Locking Nut, ASTM F594 Lock Nuts, ASTM F594 Hex Nuts. Get in touch with us with your requirement for quick quote.

Request a Quote